Leave Your Message

As we look towards the 2025 market landscape, understanding how to select the best Busbar Insulator for your specific needs becomes essential for optimizing performance and safety in electrical systems. Busbar Insulators play a critical role in ensuring electrical continuity while preventing short circuits and enhancing the overall reliability of power distribution. In this blog, we will explore various industry application cases that demonstrate the importance of choosing the right Busbar Insulator tailored to different environments and operational requirements.

Additionally, we will provide insightful statistics and compelling reasons to guide your decision-making process, ensuring that you can confidently choose an insulator that meets both your functional and regulatory needs in an increasingly demanding market.

In 2025, understanding the different types of busbar insulators and their applications will be crucial for stakeholders in the electric insulator market. Currently valued at USD 13.39 billion in 2023, the electric insulator market is projected to grow significantly, reaching USD 21.87 billion by 2032. This growth is largely driven by the rising demand for infrastructure enhancements, including the expansion of railway lines and the need for high-voltage applications, which elevate the importance of effective insulators.

Different types of busbar insulators, including ceramic, glass, and composite materials, each have unique advantages and applications. For instance, composite insulators are gaining attention for their lightweight and durable characteristics, making them suitable for modern electrical substations. Meanwhile, glass insulators, renowned for their reliability and maintenance-free nature, are anticipated to see interesting growth trends as predictive maintenance approaches become more widely adopted. As companies prepare for future demands, selecting the right type of busbar insulator will be essential for optimizing performance and meeting regulatory standards in a transforming market landscape.

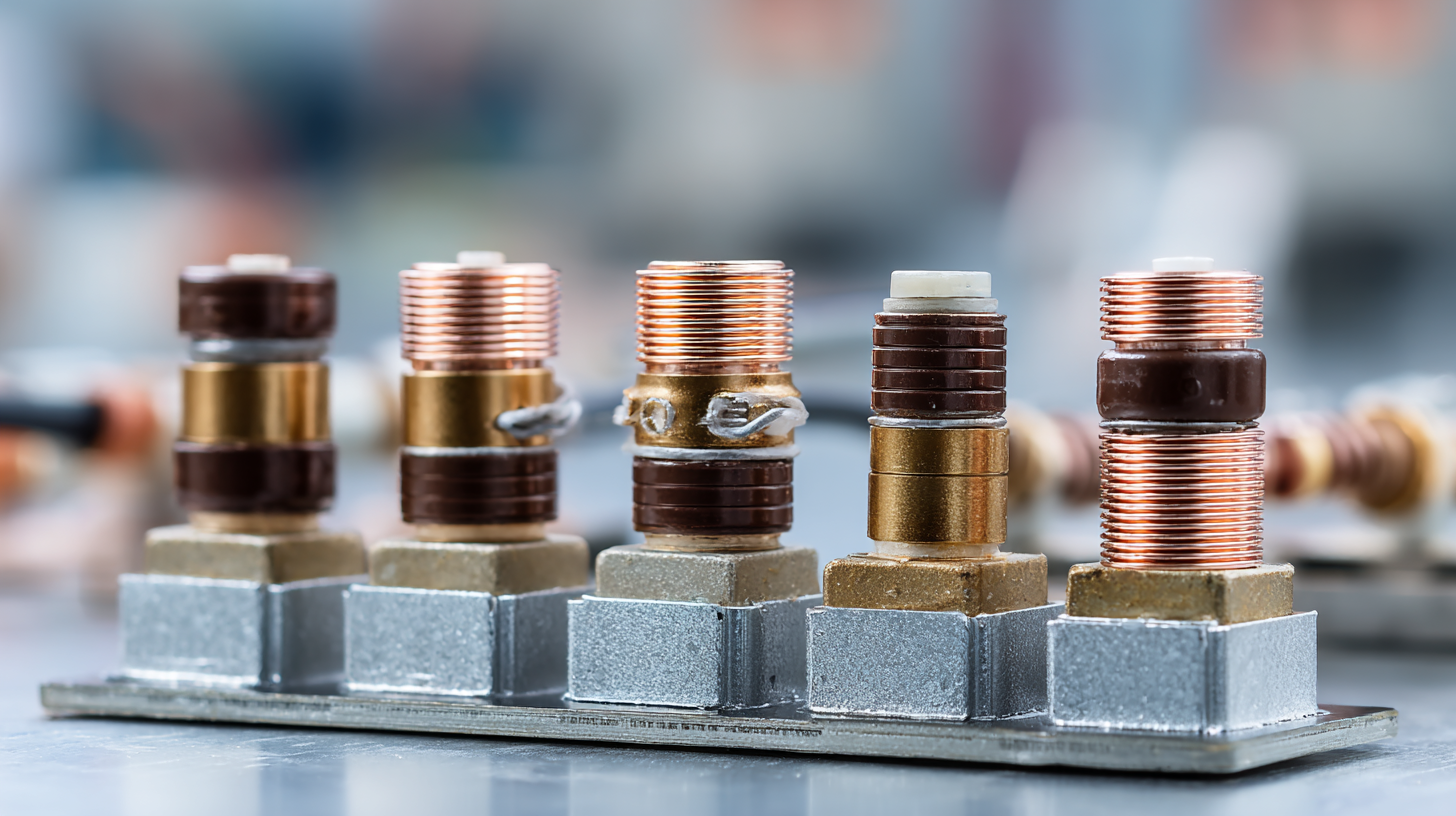

When selecting a busbar insulator, understanding the key materials and their electrical performance is crucial for achieving optimal efficiency and safety. According to a recent report by the International Electrotechnical Commission (IEC), materials such as epoxy resin and silicone are gaining popularity due to their superior dielectric properties and thermal stability. The report indicates that epoxy resin offers a dielectric strength of approximately 22 kV/mm, making it ideal for high-voltage applications, while silicone rubber exhibits excellent tracking resistance and a wide service temperature range, enhancing its reliability in diverse environmental conditions.

Additionally, recent market analyses highlight the importance of composite materials in busbar insulation. A study published by MarketsandMarkets reveals that the global busbar market is expected to reach $6.52 billion by 2025, driven in part by advancements in composite insulation technologies. These materials not only provide excellent electrical insulation but also contribute to the overall reduction of system weight, leading to easier installation and maintenance. As industries increasingly turn toward sustainable solutions, innovations in materials science will play a vital role in shaping the future of busbar technology, ensuring that users can achieve both performance and environmental responsibility.

This chart displays the dielectric strength of various materials commonly used in busbar insulators. The data indicates that polymer materials provide the highest dielectric strength, making them suitable for high-performance applications.

When selecting busbar insulators for high-voltage systems, two prominent materials come to mind: silicone and porcelain.

As the demand for eco-friendly insulator solutions continues to rise, the busbar insulator market is expected to experience significant growth. The global transformer component market is projected to exceed $16.9 billion in 2024, with an estimated compound annual growth rate (CAGR) of 7.9% from 2025 to 2034. This growth is largely driven by the upgrading of power infrastructure and the integration of renewable energy sources, reflecting a growing trend toward sustainable practices in electrical components.

In addition, the demand for eco-friendly solutions is influencing the materials used in insulator manufacturing. With applications like polyethylene (PE) and polypropylene (PP), manufacturers are increasingly exploring injection molding, film, and blow molding techniques. For instance, the heat beverage packaging market is also witnessing notable expansion, driven by consumer awareness of eco-friendly packaging, with an anticipated CAGR of 11.1% from 2025 to 2034. This reflects a broader shift in the market as stakeholders adapt to environmental considerations across various segments, including insulation solutions for busbars, emphasizing the importance of sustainability in product development.

When selecting the ideal busbar insulator for your needs, three critical factors come into play: cost, durability, and efficiency. First and foremost, cost is a significant consideration. While it's tempting to opt for the cheapest option available, it’s essential to evaluate the long-term financial implications. Higher upfront costs may lead to better quality and longevity, reducing the need for frequent replacements.

Durability is another vital aspect that should not be overlooked. Insulators are exposed to various environmental conditions, and their ability to withstand these challenges ensures consistent performance. Look for materials known for their resilience, such as porcelain or polymer, that can handle high voltage and extreme weather conditions.

Efficiency, on the other hand, relates to the insulator’s ability to minimize electrical losses. This can significantly affect operational costs and overall system performance.

**Tips:** When making your selection, consider conducting a cost-benefit analysis that factors in lifecycle costs. Additionally, invest in quality testing reports and consult with experienced professionals who can guide you based on real-world performance data. Lastly, ensure that the chosen busbar insulator aligns with your specific application requirements for optimal results.

| Insulator Type | Cost (per unit) | Durability (years) | Efficiency (%) | Temperature Rating (°C) |

|---|---|---|---|---|

| Ceramic | $15.00 | 30 | 95 | 120 |

| Polymer | $12.50 | 20 | 90 | 140 |

| Glass | $20.00 | 25 | 88 | 100 |

| Silicone | $18.00 | 15 | 92 | 150 |

| Epoxy | $22.00 | 25 | 85 | 125 |