Leave Your Message

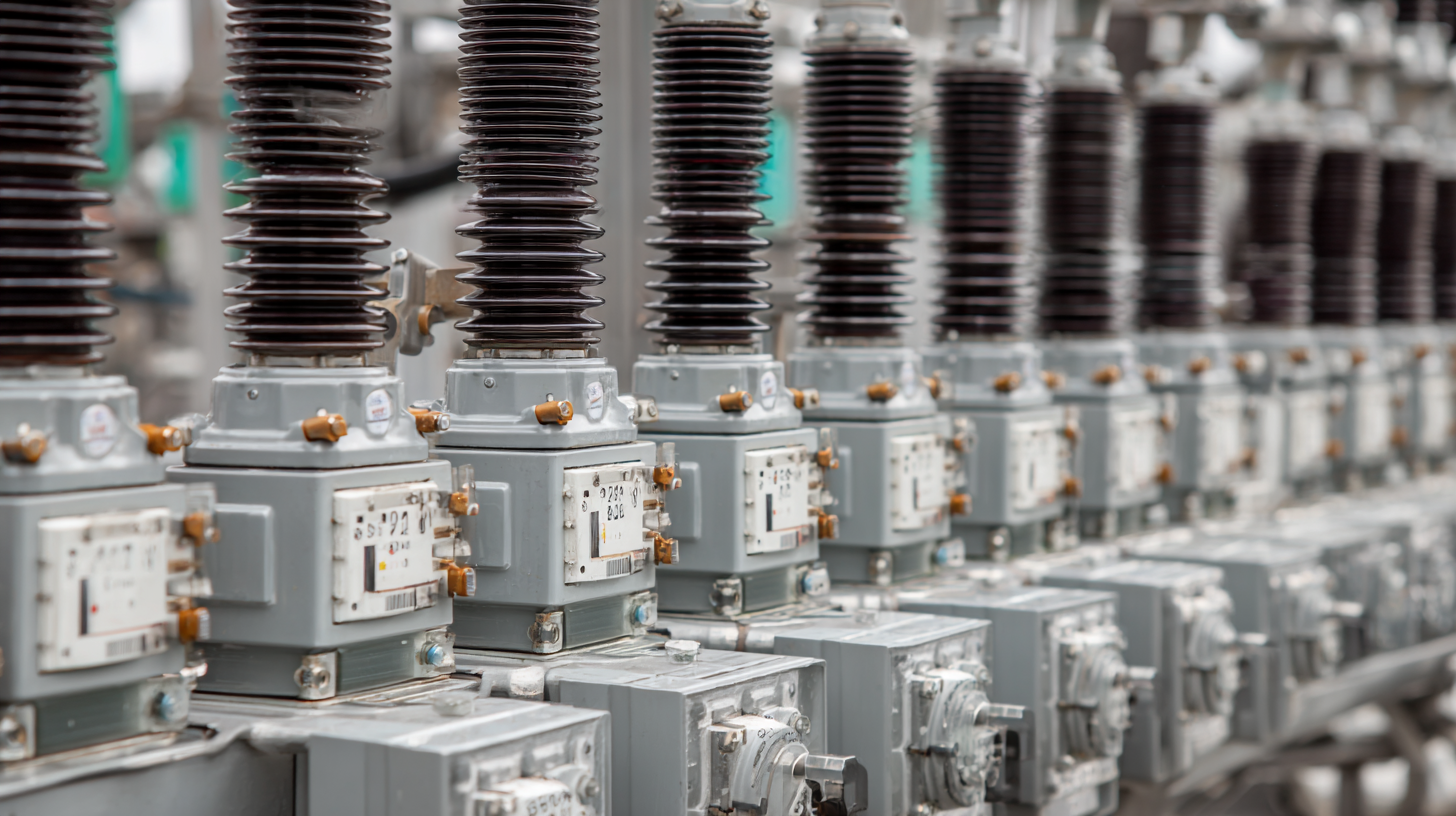

In the realm of power systems, the selection of high-quality Switchgear Insulators is crucial for ensuring reliability, safety, and efficiency. According to a recent report by the International Energy Agency (IEA), the demand for robust and dependable electrical infrastructure is expected to rise by 30% over the next decade, underscoring the importance of effective insulator solutions in managing this growth. Additionally, a study from the Electric Power Research Institute (EPRI) highlights that approximately 70% of power system failures are linked to insulator malfunctions, emphasizing their role in maintaining operational integrity. With the increasing complexity of modern electrical grids and the growing emphasis on renewable energy sources, choosing the right Switchgear Insulators has never been more critical. This article will provide you with the top five tips to make informed decisions when selecting insulators for your power systems, ultimately enhancing performance and longevity in a rapidly evolving industry.

Insulators play a critical role in ensuring the reliability and efficiency of power systems. According to a report by the International Electrotechnical Commission (IEC), the failure of insulators can lead to severe operational disruptions, including voltage spikes and power outages. In fact, insulator failures account for approximately 30% of all electrical outages, highlighting their importance in maintaining service continuity. The reliability of power systems heavily depends on the quality and specifications of insulators, which must withstand environmental factors like humidity, pollution, and temperature fluctuations.

Moreover, a recent study by the Electric Power Research Institute (EPRI) noted that advanced materials and innovative designs significantly improve the lifespan and performance of switchgear insulators. Utilizing materials like silicone rubber can enhance resistance to electrical tracking and weathering, further securing power system integrity. By choosing the right insulator, utilities can reduce maintenance costs and increase system resilience, ensuring a steady power supply to consumers. This investment in quality not only safeguards the infrastructure but also aligns with sustainability goals, paving the way for a more robust power grid.

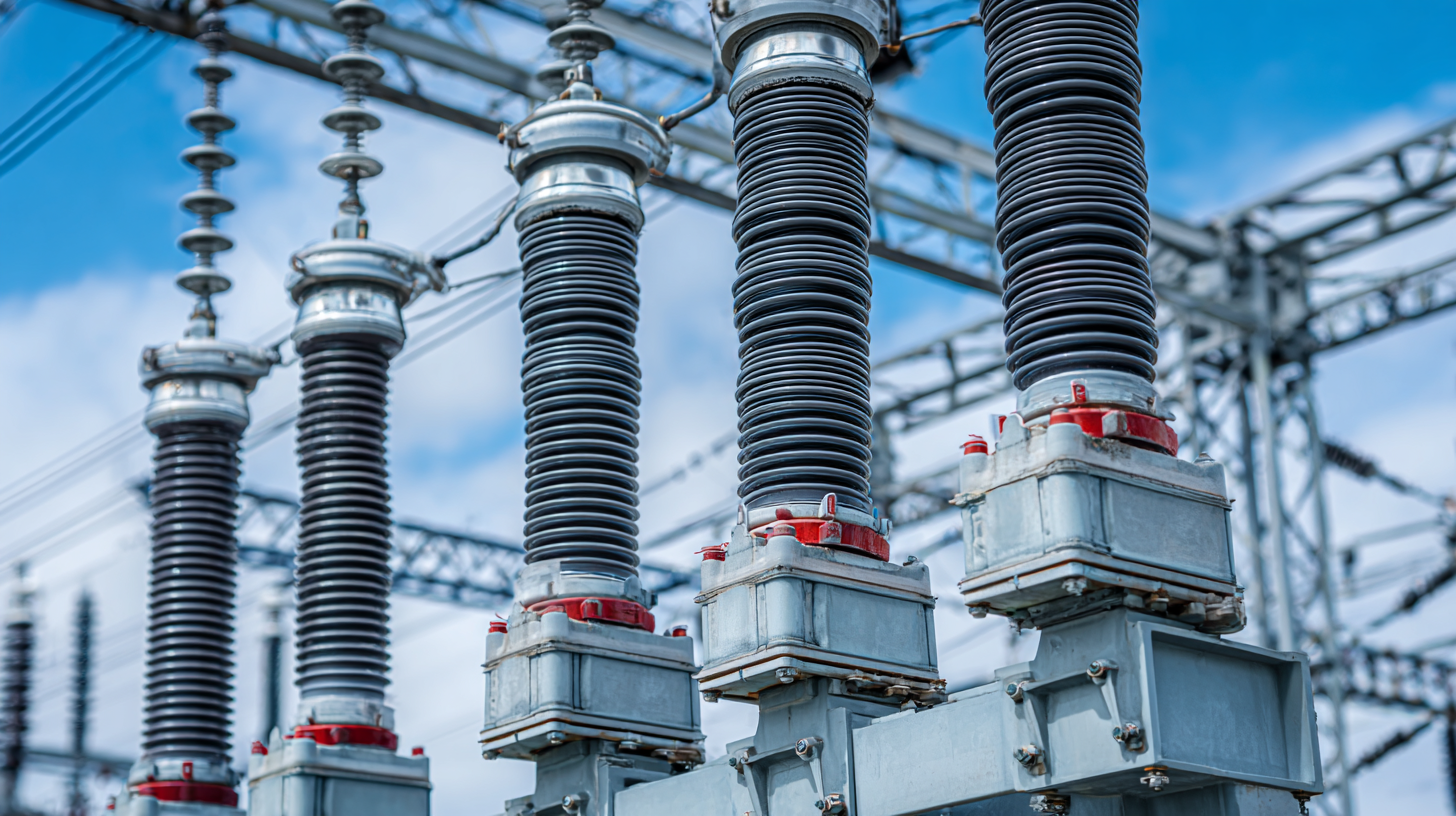

When selecting switchgear insulators for power systems, evaluating their mechanical and electrical properties is crucial for ensuring system reliability and longevity. The dielectric strength of insulators is a key factor; studies show that materials like porcelain and composite polymers exhibit dielectric strengths ranging from 20 to 40 kV/mm, making them suitable for high-voltage applications. According to a report by the International Electro technical Commission (IEC), composite insulators have gained a significant market share, attributed to their lightweight, corrosion-resistant properties, and superior tracking resistance compared to traditional materials.

Mechanical strength is another vital consideration, particularly for insulators exposed to harsh environmental conditions. The tensile strength and flexibility of insulator materials can significantly impact their performance. Data from the Electric Power Research Institute (EPRI) indicates that composite insulators can endure tensile loads of up to 20 kN, coupled with outstanding impact strength, thereby reducing the risk of failure during operational stress. Ensuring that the chosen insulator meets these mechanical and electrical property standards will ultimately safeguard the power system, minimizing maintenance costs and enhancing overall efficiency.

| Property | Description | Importance | Recommended Value |

|---|---|---|---|

| Dielectric Strength | Ability to withstand high voltage without failure. | Prevents electrical breakdown. | ≥ 30 kV/mm |

| Mechanical Strength | Resistance to mechanical stress and environmental factors. | Ensures durability and stability. | High (> 60 MPa) |

| Thermal Stability | Ability to retain properties under high temperature. | Prevents degradation in hot environments. | ≥ 150°C |

| Environmental Resistance | Resistance to UV, moisture, and pollution. | Increases lifespan and reduces maintenance. | IP65 or higher |

| Creepage Distance | The shortest path between two conductive parts along the surface. | Minimizes leakage currents. | Depends on voltage class; ≥ 25 mm/kV |

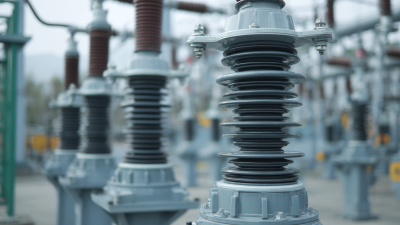

When selecting switchgear insulators, assessing environmental factors is crucial for achieving optimal performance. Various conditions such as temperature fluctuations, humidity levels, and pollution can significantly affect the insulation properties. For instance, high humidity can lead to surface leakage currents, while extreme temperatures may alter the material properties of the insulators. Therefore, it is essential to analyze local climate conditions and select insulators designed to withstand these challenges effectively.

Additionally, the presence of contaminants in the environment plays a vital role in the choice of switchgear insulators. Areas with high levels of dust, salt, or industrial pollution may require insulators with superior surface characteristics and self-cleaning properties. Insulators made of materials that resist aging and degradation under such conditions will provide reliable performance and longevity. By considering these environmental factors, engineers can ensure that the insulators not only meet operational requirements but also enhance the overall reliability of the power system.

When selecting switchgear insulators for power systems, understanding the impact of industry standards and regulations is crucial. These guidelines ensure not only the reliability and efficiency of the insulators but also their compliance with safety requirements. Key standards, such as those established by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), dictate specifications regarding material quality, operational voltage, and environmental adaptability. Adhering to these regulations helps mitigate risks associated with electrical failures and enhances the overall longevity of switchgear systems.

Moreover, local regulations can influence insulator selection, as they may impose additional criteria related to environmental impact and installation practices. For instance, guidelines regarding pollution levels can determine the type of insulator material used, particularly in regions with high atmospheric contaminants. This necessitates a careful evaluation of both international and local standards to ensure that the selected insulators meet all necessary safety and performance criteria, thus safeguarding the integrity of power distribution networks against various operational challenges.

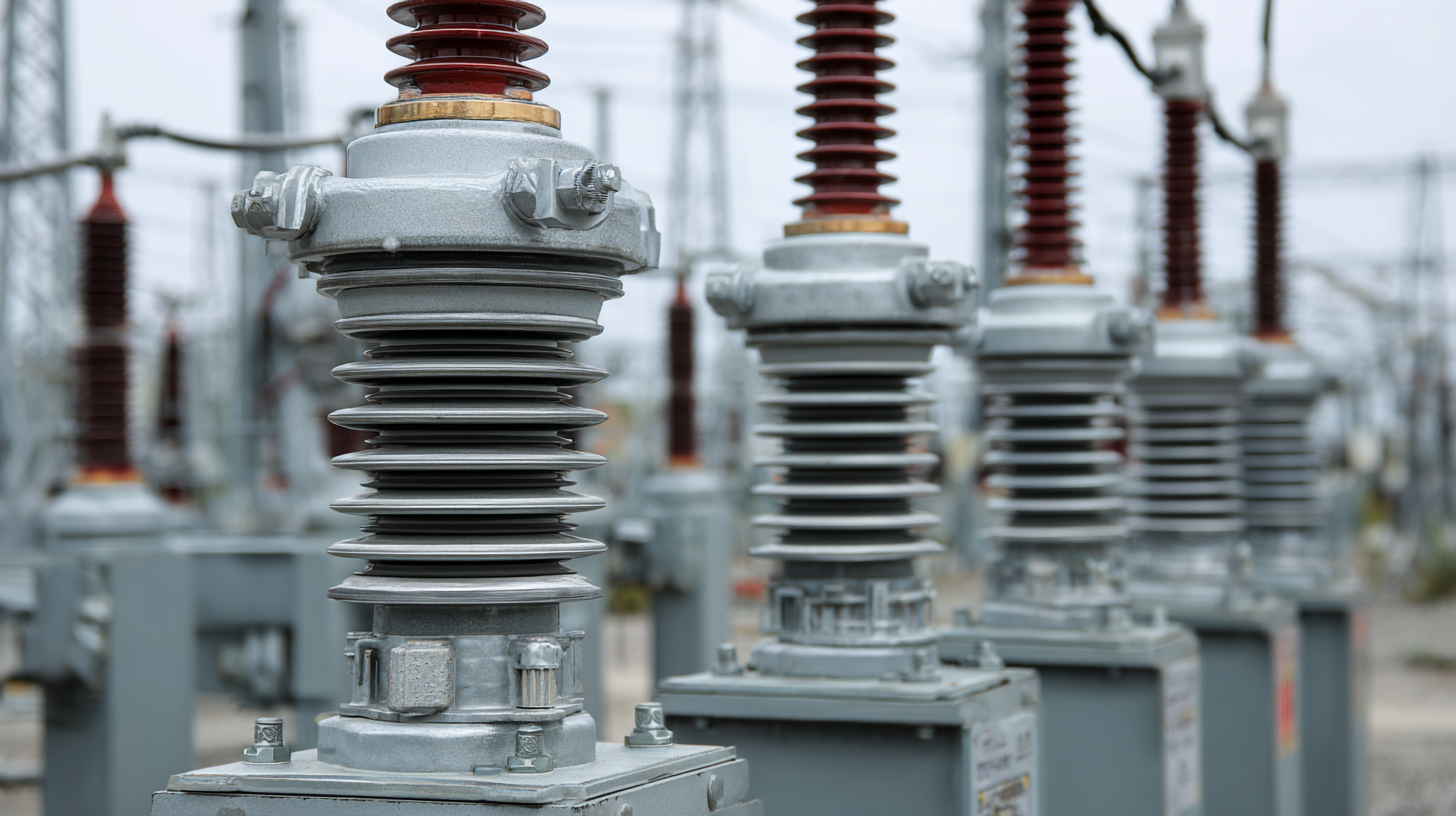

When selecting insulators for power systems, a cost-benefit analysis of different material options is crucial. Insulators play a vital role in ensuring system reliability and efficiency, and understanding the financial implications of each type can guide operators in making informed decisions. According to a report by the International Electrotechnical Commission (IEC), porcelain insulators remain a popular choice due to their durability and resistance to environmental factors, despite a higher initial cost. They typically offer a lifespan of over 40 years, providing substantial long-term savings in maintenance and replacement.

In contrast, polymer insulators, while often less expensive upfront, have a shorter lifespan — averaging around 20 years, as indicated by findings from the Electric Power Research Institute (EPRI). This can lead to increased replacement costs and higher long-term financial commitments. However, the lightweight nature of polymer insulators facilitates easier installation and reduced transportation costs, which can offset some of the initial expenditure. Ultimately, evaluating the trade-offs between initial costs, longevity, and maintenance needs is essential for optimizing expenditure in power applications.