Leave Your Message

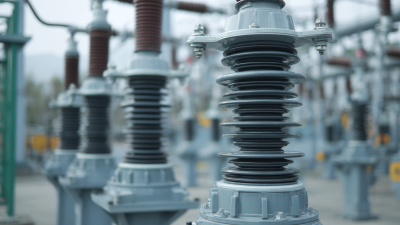

The landscape of electrical insulation is rapidly evolving, with BMC insulators standing at the forefront of innovation. BMC, or Bulk Molding Compound, has emerged as a critical material in the development of high-performance insulators due to its excellent thermal stability, electrical insulation properties, and versatility. According to a recent market report by ResearchAndMarkets, the global electrical insulation materials market is projected to reach USD 62.5 billion by 2026, growing at a CAGR of 4.2%. This surge is significantly influenced by the increasing demand for reliable and efficient insulation solutions in industries such as electric vehicles, renewable energy, and industrial automation. As BMC insulators continue to enhance their applications across diverse sectors, their role in improving sustainability and operational efficiency becomes increasingly vital. Understanding the innovations and future applications of BMC insulators is essential for stakeholders aiming to leverage this advanced material for enhanced performance and reliability.

The innovative designs in BMC (Bulk Molding Compound) insulators are paving the way for enhanced performance in various electrical applications. These new advancements are focusing on optimizing the material properties, which leads to improved thermal and electrical resistance. Manufacturers are experimenting with different composite formulations and production techniques that not only reduce weight but also increase the durability of insulators. This evolution ensures that BMC insulators can withstand extreme environmental conditions while delivering reliable insulation performance.

Additionally, the integration of smart technology into BMC insulator designs is on the rise. By incorporating sensors and monitoring systems, these insulators can provide real-time data about their operational status and environmental conditions. This feature is particularly beneficial for critical infrastructures, as it enhances safety and allows for predictive maintenance. As the demand for more resilient and efficient electrical components grows, innovations in BMC insulator design will play a crucial role in addressing these challenges, ensuring that they remain at the forefront of electrical engineering solutions.

BMC (Bulk Molding Compound) insulators are revolutionizing the electrical industry with their exceptional properties and diverse applications. One of the key benefits of BMC insulators is their outstanding mechanical strength, which provides robust protection against various environmental factors. This durability ensures reliability in high-demand electrical systems, making them an ideal choice for modern applications ranging from renewable energy systems to advanced telecommunications.

Additionally, BMC insulators exhibit superior thermal stability and resistance to electrical stress. This translates to improved performance in extreme temperature conditions, effectively minimizing the risk of thermal breakdown. Their lightweight nature also contributes to easier installation and reduced transportation costs, further streamlining production processes.

As electrical infrastructures evolve, the capability to withstand harsh conditions while maintaining efficiency is crucial, positioning BMC insulators as a cornerstone for future innovations in electrical engineering.

The advancements in BMC (Bulk Molding Compound) insulator technologies are paving the way for sustainable solutions in electrical insulation. As industries increasingly focus on environmental sustainability, BMC materials present an excellent alternative to traditional insulation options, substantially reducing ecological footprints. By integrating green pretreatment methods for cellulose extraction from lignocellulosic biomass, manufacturers can produce BMC insulators that not only meet rigorous performance standards but also minimize waste and reliance on non-renewable resources.

The advancements in BMC (Bulk Molding Compound) insulator technologies are paving the way for sustainable solutions in electrical insulation. As industries increasingly focus on environmental sustainability, BMC materials present an excellent alternative to traditional insulation options, substantially reducing ecological footprints. By integrating green pretreatment methods for cellulose extraction from lignocellulosic biomass, manufacturers can produce BMC insulators that not only meet rigorous performance standards but also minimize waste and reliance on non-renewable resources.

Moreover, the innovations in BMC technologies mirror broader trends in sustainability found across various sectors, such as the automotive industry’s shift towards composite materials and the integration of energy-efficient practices in building projects. These developments underscore the importance of adopting sustainable materials and methods that can significantly mitigate environmental impacts while promoting efficient energy use. As BMC insulator technologies evolve, their potential to contribute to a more sustainable future becomes increasingly evident, resonating with global efforts to combat climate change and enhance resource management.

The landscape of insulators is rapidly evolving with the advent of Bulk Molding Compound (BMC) insulators. Unlike traditional insulating materials such as porcelain and rubber, BMC insulators offer enhanced durability, lightweight characteristics, and superior resistance to environmental factors. These innovative materials are increasingly being favored in applications that require high-performance insulation, making them a game-changer in the industry.

Tips for choosing the right insulating material: When considering insulation for your project, assess the specific environmental conditions the material will face. BMC insulators, for instance, perform exceptionally well in extreme temperatures and resist moisture, making them suitable for outdoor applications. Additionally, compare the lifecycle costs of BMC insulators against traditional materials. Although the initial investment may be higher, the long-term savings due to reduced maintenance and replacement should not be overlooked.

Moreover, the versatility of BMC insulators enables their use in a variety of applications, from electrical components to telecommunication systems. For engineers and designers, leveraging BMC technology can lead to significant improvements in product longevity and performance. Ultimately, the choice between BMC and traditional insulating materials should reflect not just the immediate requirements but also align with future innovation trends and sustainability goals.

The BMC (Bulk Molding Compound) insulator industry is poised for significant transformation in the coming years as demand for advanced composite materials continues to rise. According to a recent report by Markets and Markets, the global BMC market share is expected to reach USD 1.7 billion by 2025, growing at a CAGR of 7.2%. This growth is driven by the increasing adoption of BMC insulators in the electrical and telecommunications sectors, thanks to their superior dielectric properties and resistance to environmental stressors.

Future trends in BMC insulator development highlight a shift towards more eco-friendly manufacturing processes and enhanced performance features. Innovations such as incorporating nanomaterials and developing hybrid composites are on the rise, which are expected to further boost the mechanical strength and thermal stability of BMC insulators. Furthermore, the push for sustainable solutions aligned with global environmental goals is encouraging industry players to invest in R&D dedicated to greener alternatives.

Future trends in BMC insulator development highlight a shift towards more eco-friendly manufacturing processes and enhanced performance features. Innovations such as incorporating nanomaterials and developing hybrid composites are on the rise, which are expected to further boost the mechanical strength and thermal stability of BMC insulators. Furthermore, the push for sustainable solutions aligned with global environmental goals is encouraging industry players to invest in R&D dedicated to greener alternatives.

Tip: When considering BMC insulators for your project, focus on suppliers that prioritize sustainability in their manufacturing processes. Also, look for products with enhanced performance metrics to ensure you are prepared for future industry standards. Always stay updated with evolving industry reports to make informed decisions about material selections.