Leave Your Message

In industrial applications, the use of Standoff Insulators is critical for ensuring safety and reliability in various electrical systems. These insulators serve as a barrier between live electrical components and grounded structures, thereby preventing electrical arcing and maintaining operational efficiency. According to a recent report by the International Electrotechnical Commission, improper use or failure of insulation systems contributes to approximately 30% of electrical equipment failures, highlighting the importance of robust standoff insulation solutions. However, challenges such as environmental stressors, mechanical loading, and material degradation can significantly impact the performance of Standoff Insulators, leading to increased maintenance costs and downtime. In this blog, we will explore the specific challenges faced by Standoff Insulators in industrial settings and discuss viable solutions to enhance their effectiveness and longevity.

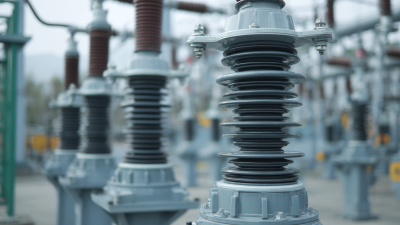

Standoff insulators play a crucial role in enhancing electrical safety across various industrial applications. These insulators are designed to maintain a safe distance between conductive components and grounded surfaces, ensuring that high voltages do not inadvertently create safety hazards. By providing physical separation, standoff insulators help to mitigate the risk of short circuits and electrical arcs, which can lead to equipment damage, operational downtime, and even hazardous situations for personnel.

In addition to their protective function, standoff insulators are essential for maintaining the integrity of electrical systems in harsh industrial environments. They are engineered to withstand extreme temperatures, moisture, and chemical exposure, which are common in manufacturing, construction, and utility sectors. This durability not only enhances the lifespan of electrical equipment but also promotes reliable performance, aligning with the industry's growing emphasis on safety and efficiency. By implementing robust standoff insulation solutions, industries can safeguard their operations and contribute to a safer working environment for all employees.

Standoff insulators play a crucial role in various industrial applications, particularly in harsh environments where reliability is paramount. These insulators are designed to withstand extreme conditions such as high temperatures, corrosive substances, and mechanical stresses. However, they face significant challenges that can compromise their performance. For instance, adverse weather conditions can lead to material degradation, making it essential for manufacturers to innovate and enhance the durability of these components.

In the context of geopolitical tensions that often correlate with industrial advancements, the challenges of standoff insulators are further compounded. Much like the evolving military strategies observed in the standoffs between nations, industries must adapt to ensure their insulators are resilient against the changing demands of their environments. As seen in the recent dynamics between India and China, the strategic deployment of resources is critical, paralleling how industries might need to allocate funding effectively to research and development. By addressing these challenges head-on, manufacturers can bolster the efficacy of standoff insulators, ensuring they meet the rigorous demands of today’s industrial landscape.

| Challenge | Description | Impact on Performance | Mitigation Strategies |

|---|---|---|---|

| Corrosion | Exposure to aggressive chemicals and moisture. | Reduced insulator lifespan and increased failure rates. | Use of corrosion-resistant materials and coatings. |

| Mechanical Stress | Vibrations and physical impacts from machinery. | Possible cracking or breakage of insulators. | Reinforced designs and flexible mounting options. |

| Thermal Cycling | Frequent changes in temperature affecting materials. | Increased risk of thermal expansion issues. | Thermal management solutions and material selection. |

| Pollution | Accumulation of dust, grime, and other pollutants. | Decreased dielectric strength and performance. | Regular cleaning and hydrophobic surfaces. |

| Electrical Stress | High voltage applications leading to dielectric breakdown. | Increased risk of arcing and short circuits. | Proper insulation design and voltage ratings. |

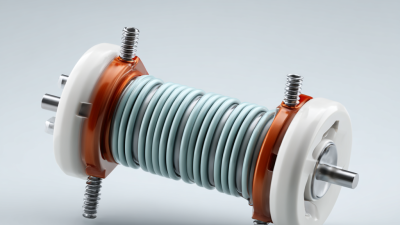

Material selection for standoff insulators in industrial applications is critical, as it directly influences both durability and electrical performance. Insulators must withstand various environmental conditions, including UV exposure, moisture, and temperature fluctuations, all while maintaining their insulating properties. Choosing the right materials, such as silicone rubber or glass, can significantly enhance the lifespan and reliability of these components in demanding environments.

**Tip:** When selecting materials, consider the specific environmental conditions and the electrical load requirements to strike an optimal balance between durability and performance. A detailed analysis of potential wear factors can help in making informed decisions.

Furthermore, it is essential to evaluate the mechanical stresses that insulators will face. Materials with high dielectric strength may be advantageous, but they should also exhibit resilience to physical impacts and degradation over time. This multifaceted approach not only ensures enhanced performance but also minimizes the risk of failure in critical applications.

**Tip:** Regular maintenance checks and assessments can help identify wear and tear early, allowing for timely replacements or adjustments before issues occur, thus safeguarding operational integrity.

Standoff insulators play a crucial role in ensuring the safety and efficiency of electrical systems in industrial applications. However, their reliability can be compromised due to various environmental factors, mechanical stresses, and aging. To enhance the performance of standoff insulators, it’s essential to adopt innovative solutions that address these challenges. This includes the use of advanced materials designed to withstand extreme conditions, which can significantly improve the durability and functionality of insulators.

Tips for improving standoff insulator reliability include conducting regular inspections to identify potential wear and tear. Implementing a preventive maintenance schedule not only mitigates unexpected failures but also extends the overall lifespan of insulators. Additionally, consider employing coatings or treatments that enhance resistance to moisture and contaminants, which can lead to electrical tracking or degradation over time.

Another effective approach is to leverage smart technology. Introducing sensors that monitor the condition and performance of standoff insulators can provide real-time data to the maintenance team, allowing for prompt action if anomalies are detected. This proactive strategy helps ensure that industrial systems remain efficient and safe, minimizing downtime and maintenance costs.

As industries evolve, the demand for advanced standoff insulator technology is becoming increasingly critical to address the challenges posed by harsh operational environments. Recent data from the International Energy Agency (IEA) indicates that the industrial sector is expected to witness a growth rate of approximately 4.5% annually in the adoption of high-voltage insulator systems over the next five years. This is largely driven by a need for greater durability and reliability in electricity transmission and distribution systems, particularly within renewable energy sectors like wind and solar.

Future trends in standoff insulator technology are characterized by innovations in materials and manufacturing processes. According to a report by MarketsandMarkets, the global standoff insulator market is projected to reach $1.2 billion by 2026, with ceramic and polymer insulators gaining significant traction due to their lightweight nature and superior electrical performance. Advances in smart materials and nanotechnology are also set to revolutionize the design of insulators, promising enhanced thermal resistance and improved mechanical strength. These innovations will enable industries to minimize maintenance costs while ensuring operational safety and efficiency.