Leave Your Message

When it comes to electrical projects, selecting the appropriate components is crucial for ensuring safety and efficiency. One key component that often deserves more attention than it receives is the Busbar Insulator. These insulators play a vital role in preventing electrical leakage and maintaining the integrity of the busbar system, which is essential for distributing electricity effectively in various applications. With numerous types of Busbar Insulators available on the market, each with unique characteristics and specifications, choosing the right one can be a daunting task. This blog will provide a comprehensive guide to understanding the different types of Busbar Insulators, their features, and the factors to consider when making your selection. By the end, you’ll be equipped with valuable insights that will help you make informed decisions for your electrical projects.

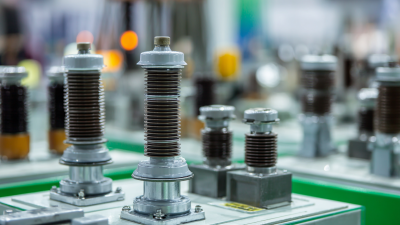

Busbar insulators may seem like a minor component in electrical systems, but their role is crucial in ensuring safety, reliability, and efficiency. These insulators are designed to support and separate busbars, which are essential for distributing electrical power. By preventing unintended contact, busbar insulators minimize the risk of short circuits and electrical arcing, which can lead to severe damage or even catastrophic failures in electrical installations.

When selecting the right busbar insulator, consider the material and voltage rating. Common materials include fiberglass, ceramic, and thermoplastic. Each material offers different benefits, from high thermal resistance to mechanical strength. It’s essential to match the insulator with the voltage level of your project to ensure optimal performance.

Tips: Always check the temperature range of the insulator to avoid breakdown under extreme conditions. Additionally, evaluate the environmental factors like humidity and pollution, as these can affect the longevity of the insulators. Lastly, consider the installation space; ensure there’s enough room for any potential thermal expansion, as this can impact the effectiveness of the insulation in the long run.

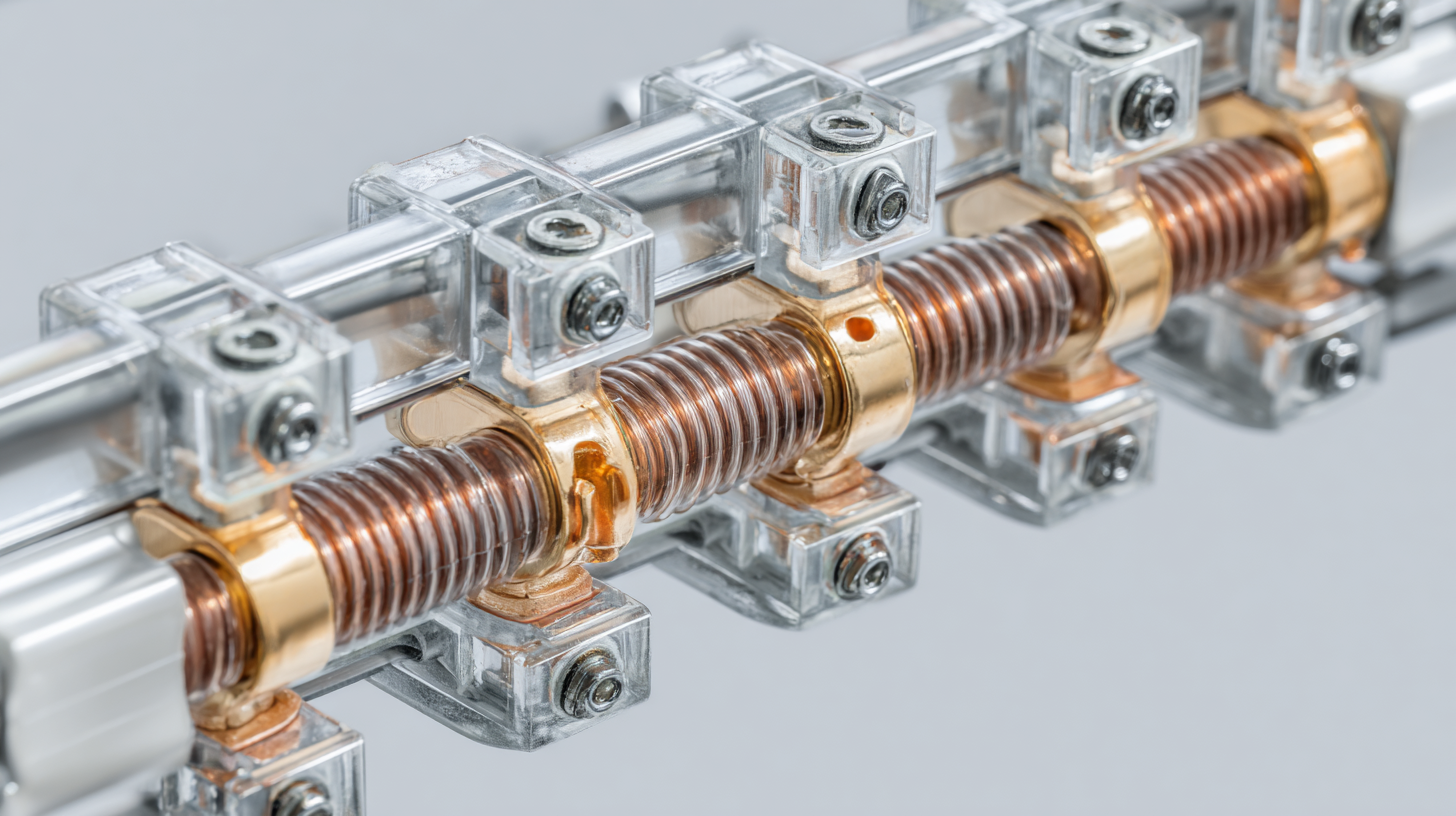

When selecting a busbar insulator for your electrical projects, several key factors come into play. First and foremost, the material of the insulator is crucial. Common materials include porcelain, glass, and various polymers, each offering different levels of electrical resistance and mechanical strength. Porcelain insulators, for instance, are known for their durability and resistance to harsh environmental conditions, making them ideal for outdoor applications. Conversely, polymer insulators may be lightweight and easier to install, making them suitable for compact designs in limited spaces.

Another significant consideration is the voltage rating of the busbar insulator. It is essential to choose an insulator that can withstand the maximum voltage your system will encounter. Exceeding the voltage rating can lead to dielectric breakdown, posing a risk of failure. Additionally, evaluating thermal performance is vital, as insulators must manage heat dissipation effectively to maintain operational efficiency. Ensuring that the insulator can handle temperature fluctuations and operates within the safe temperature range will prolong its lifespan and enhance overall system reliability.

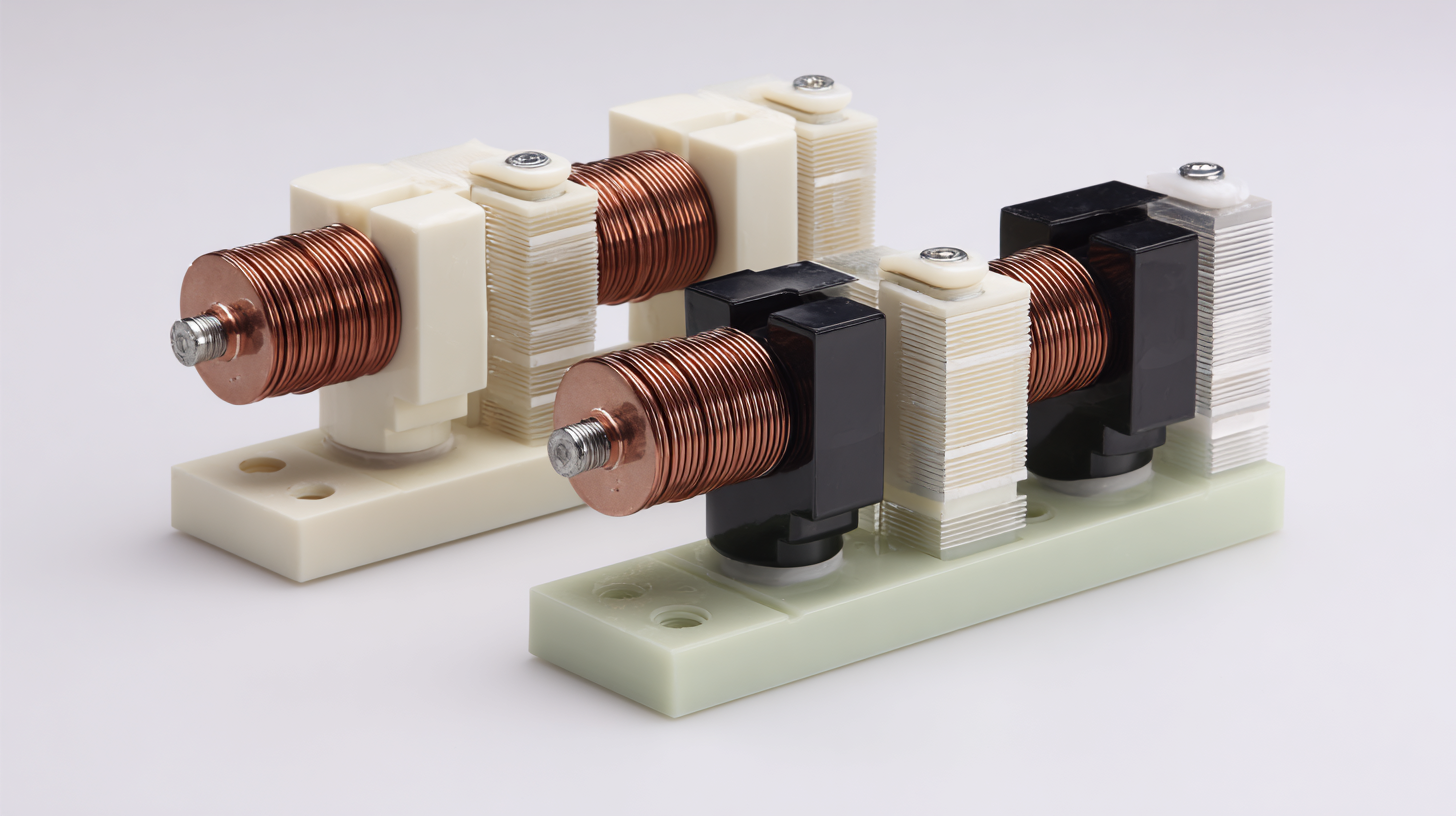

When it comes to selecting a busbar insulator for electrical applications, the choice of material can significantly influence both performance and reliability. Ceramic insulators have a long-standing reputation in the industry, known for their superior thermal stability and mechanical strength. According to a recent report by the Electric Power Research Institute (EPRI), ceramic insulators demonstrate a dielectric strength of approximately 15 kV/mm, making them ideal for high-voltage environments. Their ability to withstand extreme temperatures and resist environmental degradation further enhances their longevity, with some manufacturers stating a service life of over 30 years.

On the other hand, polymer insulators are gaining traction due to their lightweight nature and resistance to environmental stressors. A study published by the Institute of Electrical and Electronics Engineers (IEEE) highlights that polymer insulators often exhibit better hydrophobic properties, which can reduce the accumulation of contaminants and improve overall performance in adverse weather conditions. Additionally, polymer insulators can provide a dielectric strength comparable to ceramics, often exceeding 10 kV/mm. Despite their shorter lifespan, with estimates around 25 years, the ease of installation and maintenance makes them an appealing choice for many modern electrical projects, particularly in urban settings where weight and space constraints are critical.

When selecting the appropriate busbar insulator for electrical projects, it’s essential to consider industry standards and regulations that govern insulation materials and tolerances. These regulations ensure safety, reliability, and efficiency in electrical systems. Familiarizing yourself with standards such as IEC 60269 or ANSI C37.20.3 can greatly enhance your decision-making process. Different applications may have specific requirements, so always check local regulations as they can vary significantly by region.

Tip: Before finalizing your choice, always validate that the insulator materials comply with the specified electrical and thermal properties required for your project. This ensures it can withstand the required voltage and environmental conditions.

Additionally, consulting with manufacturers about their products' compliance with industry standards can provide valuable insights. Many manufacturers offer certification documentation that reassures the performance and reliability of their insulators, including resistance to moisture, pollution, and high temperatures.

Tip: Leverage online resources and industry forums to gather feedback and experiences from other professionals. This real-world insight can be invaluable in making an informed choice and avoiding common pitfalls in busbar insulator selection.

The choice of busbar insulators can significantly impact the efficiency and safety of electrical projects. Recent case studies highlight successful implementations that demonstrate the importance of selecting the right materials and designs. For example, a project at a major industrial facility in the Midwest opted for polymer busbar insulators over traditional porcelain. This choice resulted in a 30% reduction in maintenance costs, as indicated by a report from the International Electrotechnical Commission (IEC), which emphasizes the durability and lower upkeep requirements of modern materials.

In another instance, a renewable energy project in California utilized silicone rubber insulators, which provided superior performance in harsh environmental conditions. According to a National Renewable Energy Laboratory (NREL) study, these insulators enhanced the system's reliability by 25%, minimizing downtime and ensuring continuous operation. The case studies illustrate that by carefully selecting busbar insulators suited to specific environmental and operational requirements, projects can improve efficiency and reduce long-term costs significantly.

| Project Name | Busbar Insulator Type | Installation Environment | Load Capacity (A) | Project Outcome |

|---|---|---|---|---|

| Industrial Factory Upgrade | Epoxy Resin Insulator | Indoor, High Humidity | 2000 | Improved performance and reduced downtime |

| Renewable Energy Facility | Porcelain Insulator | Outdoor, Solar Site | 1500 | Enhanced durability against weather conditions |

| Data Center Expansion | Composite Insulator | Indoor, Controlled Environment | 3000 | Increased system reliability and efficiency |

| Substation Upgrade | Silicone Insulator | Outdoor, High Pollution Area | 2500 | Reduced maintenance costs and extended lifespan |

| Telecom Network Expansion | Glass Fiber Insulator | Indoor/Outdoor, Varying Conditions | 1800 | High performance with minimal electrical losses |