Leave Your Message

In the ever-evolving landscape of electrical engineering, the choice of components plays a critical role in ensuring safety and efficiency. Among these components, the low voltage insulator stands out as an essential element in the electrical infrastructure. As we approach the year 2025, it's crucial for both professionals and DIY enthusiasts to understand how to select the most effective low voltage insulator for their specific electrical needs. The right insulator not only enhances performance but also minimizes the risk of faults and ensures compliance with safety standards.

This guide aims to simplify the selection process by presenting the "Top 10" considerations you should keep in mind when choosing a low voltage insulator. From material types to environmental conditions, each factor influences the durability and effectiveness of the insulator. By paying attention to these critical aspects, you'll be better equipped to make an informed decision that aligns with your project requirements and budget. Whether you're involved in residential installations or large-scale industrial projects, understanding the intricacies of low voltage insulators is paramount for achieving reliable and safe electrical systems.

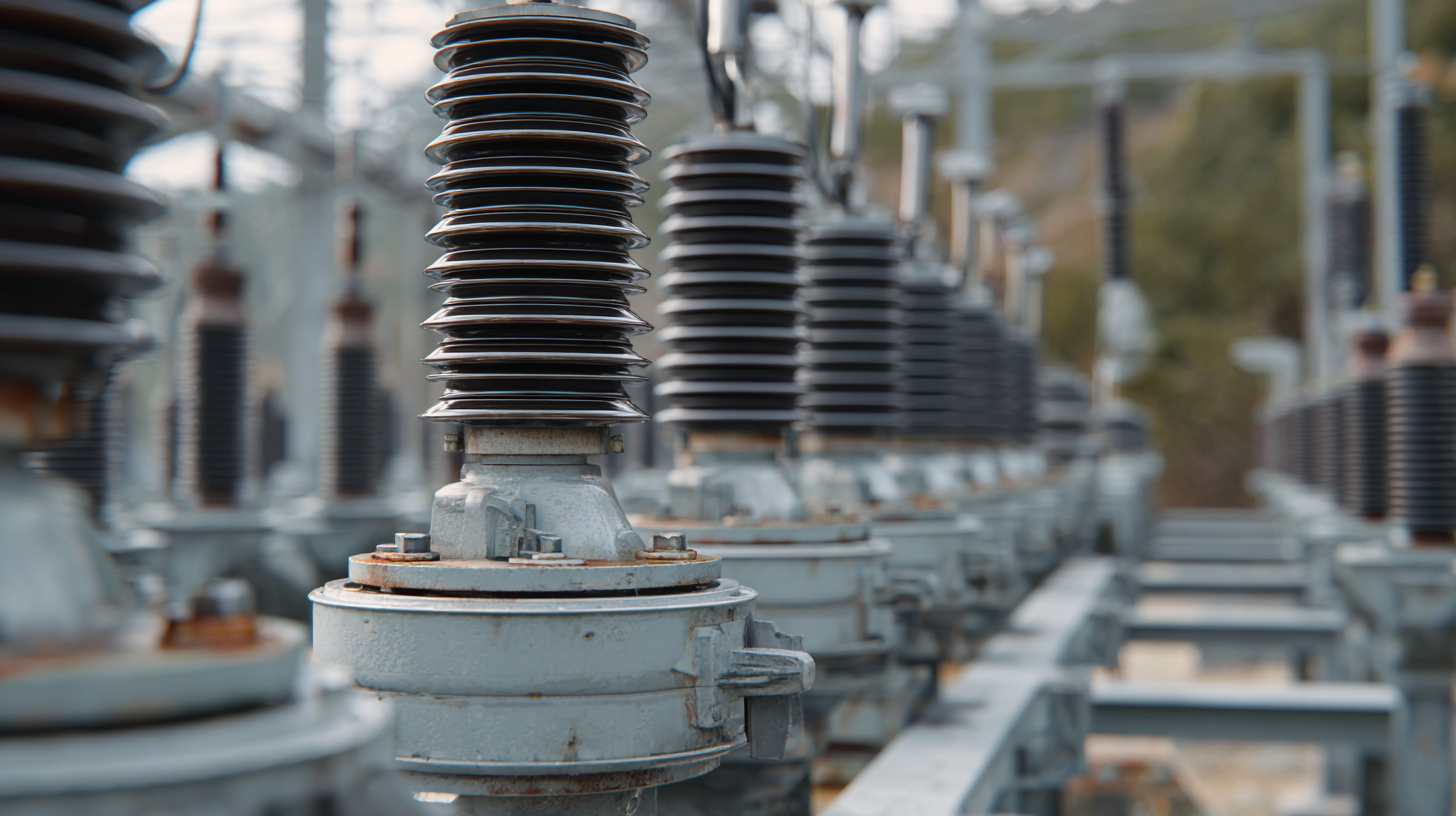

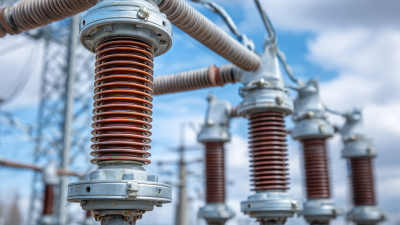

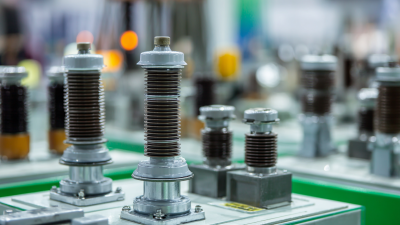

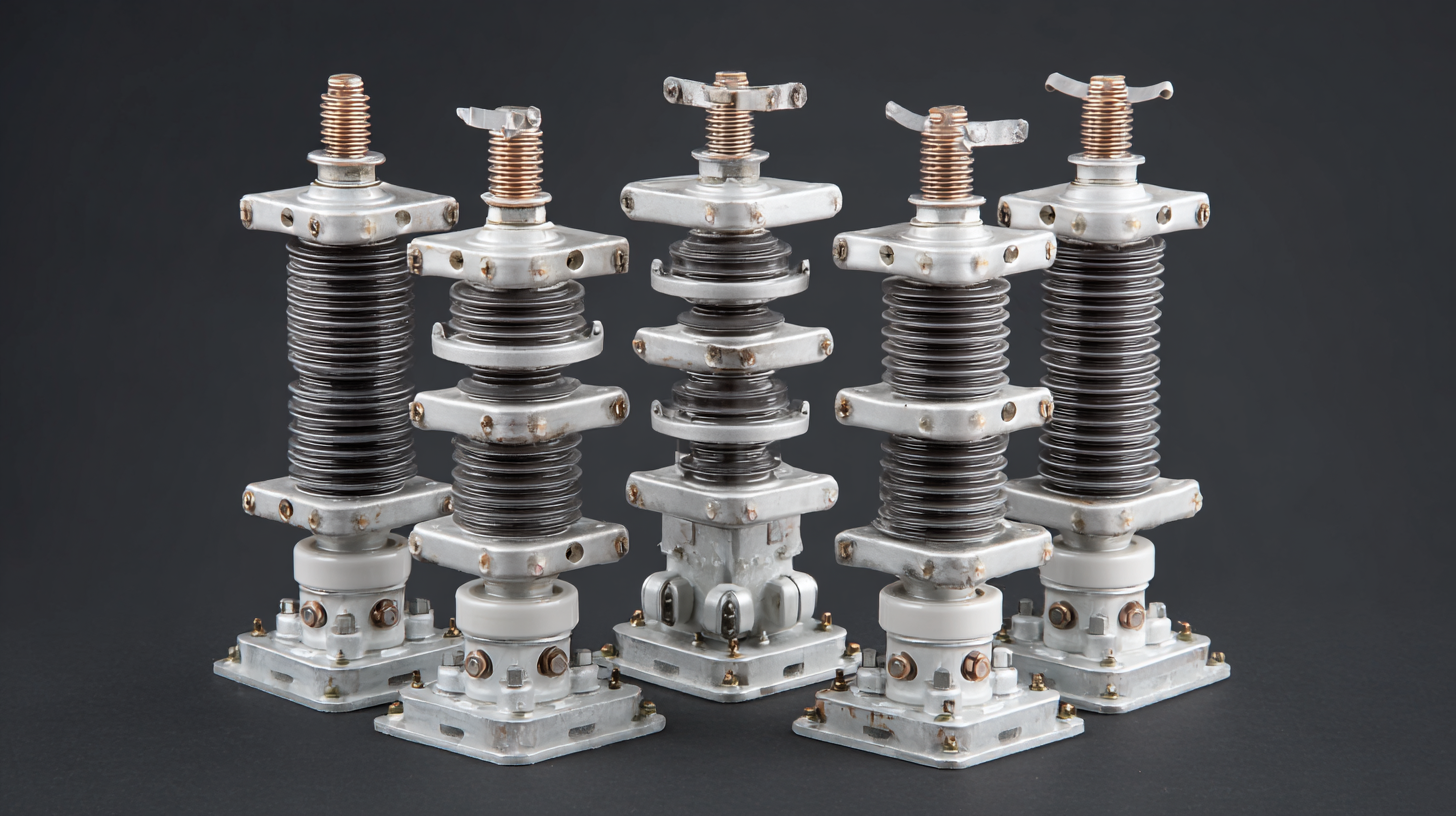

Low voltage insulators are critical components in electrical installations, ensuring safety and efficiency in power distribution. The most common types include ceramic insulators, glass insulators, and polymer insulators, each offering distinct advantages based on their materials and construction. According to the International Electrotechnical Commission (IEC), ceramic insulators are preferred for their high mechanical strength and resistance to weathering, making them ideal for outdoor applications. In contrast, polymer insulators are lightweight and have superior hydrophobic properties, which reduce contamination issues and are suitable for environments with high pollution levels.

When selecting low voltage insulators, it is essential to consider specific applications. For instance, the Electric Power Research Institute (EPRI) indicates that polymer insulators have emerged as a favorable choice for urban areas, where their lightweight nature allows for easier handling and installation. On the other hand, glass insulators are often utilized in high-voltage transmission lines due to their excellent electrical properties and longevity. It is crucial to evaluate factors such as environmental conditions, voltage levels, and required mechanical strength to choose the most suitable insulator type for your electrical needs effectively.

| Type of Insulator | Material | Voltage Rating (kV) | Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Porcelain Insulators | Porcelain | 1-36 kV | Low voltage power lines | Durable, high dielectric strength | Heavy, can break if dropped |

| Polymer Insulators | Composite materials | 1-15 kV | Substation applications | Lightweight, resistant to vandalism | Less durable in extreme temperatures |

| Glass Insulators | Glass | 1-30 kV | Telecommunication lines | High mechanical strength, long life | Fragile, heavier than other types |

| Dry-Type Insulators | Plastic | 1-15 kV | Indoor applications | Compact size, easy installation | Not suitable for outdoor use |

When selecting a low voltage insulator for your electrical needs, several key features must be considered to ensure safety and efficiency. One of the critical aspects is the material used in the insulator. Polymer-based insulators, for instance, are gaining popularity due to their excellent dielectric properties and resistance to environmental factors. According to recent industry analyses, the demand for polymer insulators is projected to increase significantly, driven by their lightweight nature and superior performance compared to traditional ceramic options.

Another essential feature to consider is the insulator's voltage rating and its ability to withstand transient overloads, which is crucial for maintaining system reliability. In distribution substations, particularly, the market size for various types of insulators is being shaped by technological advancements and the growing use of gas-insulated and air-insulated solutions. Statistics show that GIS technologies have been embraced for their compact design and reduced footprint, which further emphasizes the need for robust insulators that align with the evolving infrastructure demands.

By focusing on these key characteristics, one can make informed decisions to optimize electrical projects while adhering to industry standards.

When selecting low voltage insulators for electrical applications, the choice of material plays a crucial role in ensuring durability and efficiency. Common materials used for low voltage insulators include porcelain, glass, and various types of polymers. Porcelain insulators are favored for their excellent electrical insulation properties and resistance to harsh weather conditions. They provide a reliable solution for outdoor applications, where exposure to moisture and temperature fluctuations can significantly affect performance.

On the other hand, glass insulators offer transparency and high mechanical strength, making them suitable for visual inspections of the insulator's condition. Their durability against UV radiation also enhances their longevity in outdoor environments. Meanwhile, polymer insulators, often made of materials like silicone rubber, provide lightweight and flexible options that are highly resistant to tracking and erosion. This versatility makes them ideal for modern, compact designs in urban settings. Each material has its unique advantages, and understanding these can help in choosing the best insulator to meet specific electrical needs.

When selecting a low voltage insulator, understanding the balance between cost and performance is crucial. Insulators play a critical role in ensuring the safety and efficiency of electrical systems, so it's important to evaluate how different materials and designs influence both expenses and functionality. High-performance insulators may come with a steeper price tag, but investing in quality can lead to long-term savings by reducing the risk of failures and maintenance costs.

One strategy for making an informed choice is to conduct a thorough cost-benefit analysis. Consider factors such as the environmental conditions where the insulators will be used, the expected lifespan, and the specific electrical requirements of your project. While lower-cost options may seem appealing initially, they may not withstand harsh conditions, leading to premature replacement. Ultimately, selecting an insulator that strikes the right balance between affordability and reliability will ensure your electrical systems remain safe and efficient over time.

This chart evaluates the performance and cost of various low voltage insulators in the market. The data showcases the relationship between the cost (in USD) and the performance rating (from 1 to 10) of selected insulators.

When it comes to installing low voltage insulators, adhering to proper guidelines and best practices is essential for ensuring safety and efficiency. One key aspect is to choose the right type of insulator based on the specific electrical application. Low voltage systems, which typically operate at 1000 volts or less, require insulators that can withstand environmental factors such as moisture and temperature fluctuations. Selecting high-quality materials that meet industry standards will help maintain the integrity of your electrical setup.

**Tips:** Always start by evaluating your project's requirements, including the load and environmental conditions. When installing, ensure that the insulator is securely mounted and that all connections are tight to prevent any potential electrical hazards. Regularly inspect your insulators for any signs of wear or damage, especially after harsh weather conditions, to guarantee long-term reliability.

Additionally, consider using insulators designed for easy installation—these can significantly reduce the time and complexity involved in the setup process. Following these best practices will not only enhance safety but also improve the overall performance of your electrical systems.