Leave Your Message

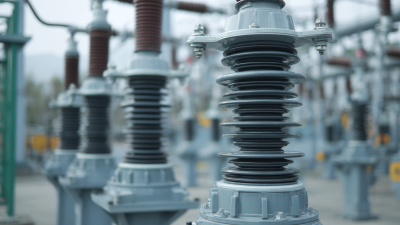

The effectiveness and reliability of electrical systems heavily depend on various components, among which Busbar Insulators play a critical role. These insulators are designed to maintain electrical separation between busbars and other components, preventing short circuits and ensuring safety in high-voltage environments. According to the International Electrotechnical Commission (IEC), the global busbar market is projected to reach USD 4.6 billion by 2025, highlighting the significance of high-quality insulation materials in enhancing the operational efficiency of electrical grids. Furthermore, the use of advanced materials such as silicone rubber and porcelain in Busbar Insulator production has been shown to improve performance under extreme weather conditions. The increasing demand for renewable energy and smart grid solutions further underscores the necessity for reliable Busbar Insulators, which facilitate better energy distribution and enhance system resilience. This article delves deeper into the functionality of Busbar Insulators and their pivotal role in modern electrical systems.

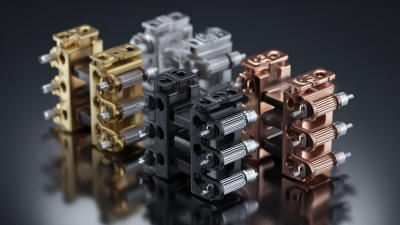

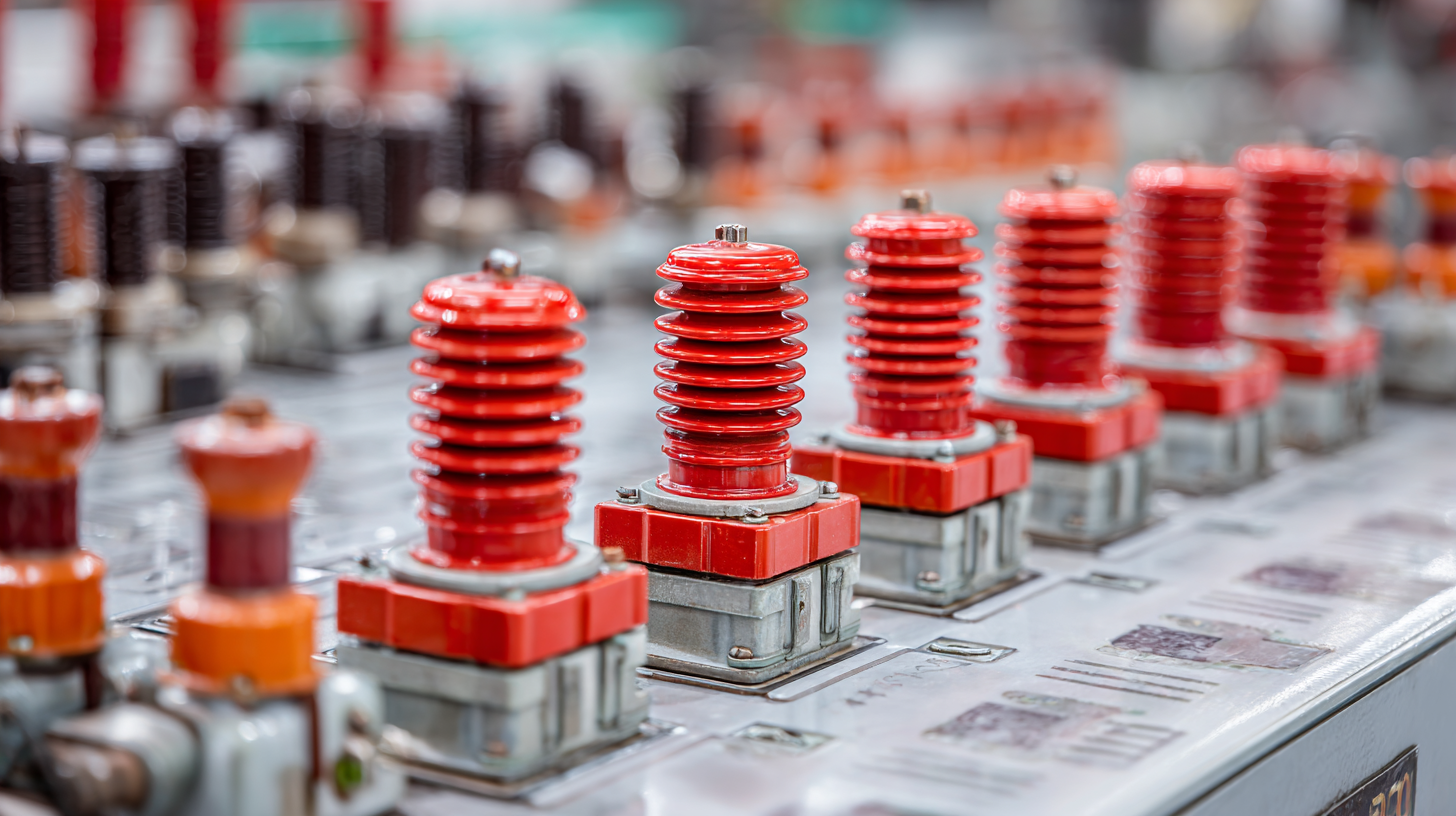

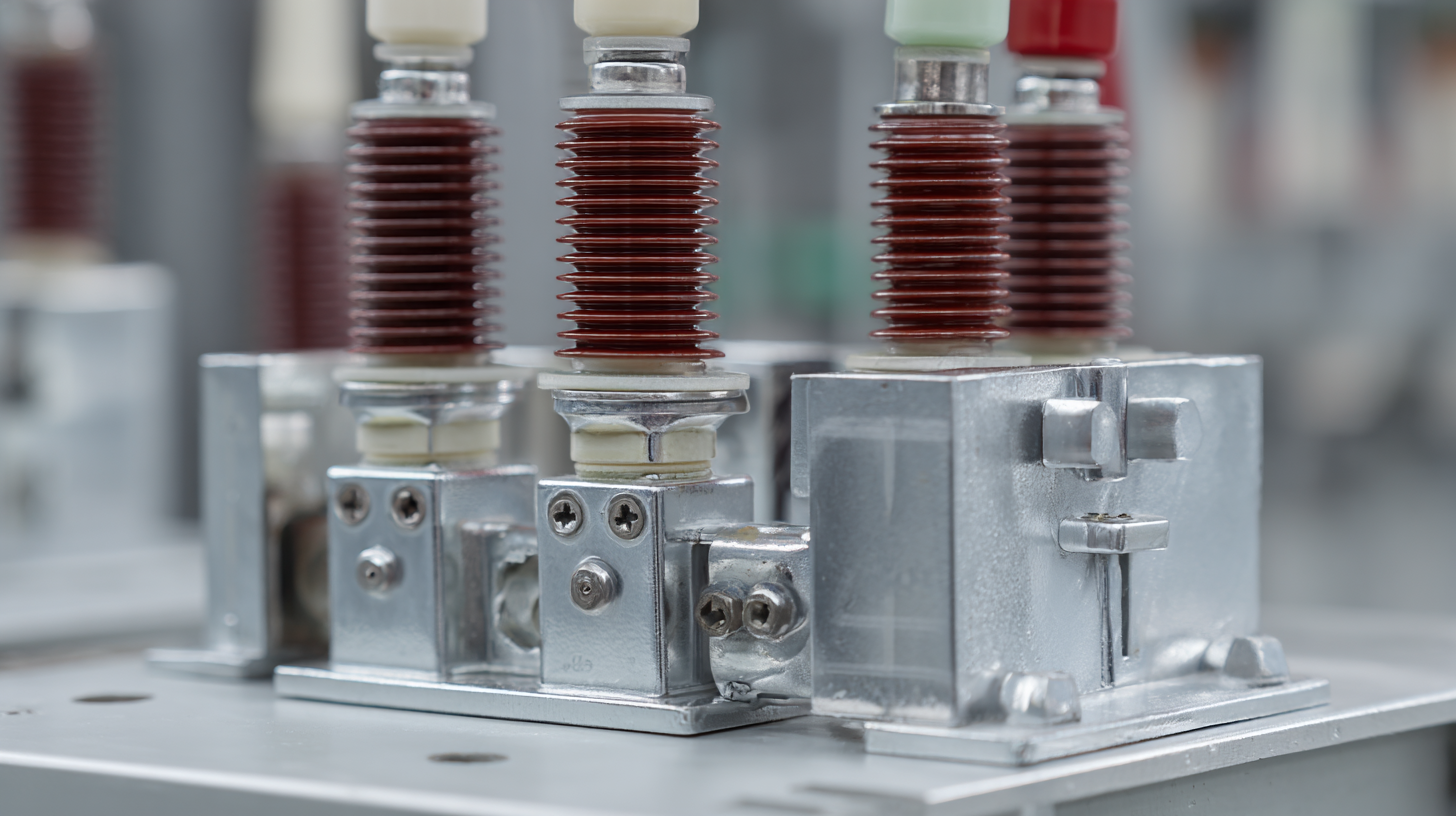

Busbar insulators play a critical role in electrical systems by providing support and separation between busbars and other conductive components. These insulators are essential for maintaining the integrity of electrical circuits, preventing short circuits, and ensuring the safe operation of power distribution systems. They are typically made from materials such as porcelain or polymer, which offer high dielectric strength, thermal resistance, and mechanical durability. The design and placement of busbar insulators can significantly impact the efficiency and reliability of electrical installations.

**Tip:** When selecting busbar insulators, consider factors such as environmental conditions, voltage levels, and installation space. Properly rated insulators ensure that your electrical system operates safely and effectively under varying conditions.

Moreover, the functionality of busbar insulators extends beyond mere support. They also help to minimize energy losses and reduce the risk of electrical failures. Their ability to withstand high voltages and temperatures makes them a vital component in substations, switchgear, and various industrial applications. Choosing the right insulator not only contributes to the longevity of the equipment but also enhances overall system performance.

**Tip:** Regularly inspect and maintain busbar insulators to ensure they remain free from contaminants and damage, which can compromise their effectiveness and lead to potential hazards.

| Parameter | Description | Material | Application |

|---|---|---|---|

| Dielectric Strength | Ability to withstand high voltage without conducting | Ceramic, Composite | High Voltage Applications |

| Thermal Stability | Resistance to thermal stress and high temperatures | Polymer, Rubber | Power Distribution |

| Mechanical Strength | Ability to withstand mechanical stress and impacts | Fiberglass, Metal | Industrial Applications |

| Environmental Resistance | Ability to withstand weathering, UV exposure and chemical exposure | Composite, Glass | Outdoor Applications |

| Cost-Effectiveness | Balance between performance and cost | Various Materials | General Applications |

Busbar insulators play a crucial role in the functionality and safety of electrical systems by preventing electrical leakage and ensuring the efficient transfer of power. There are several key types of busbar insulators commonly used in various applications. For instance, porcelain insulators are favored for their durability and resistance to environmental factors, making them ideal for outdoor applications. On the other hand, polymer insulators, known for their lightweight and flexibility, are increasingly being utilized in modern installations where weight and space constraints are critical.

**Tip:** When selecting busbar insulators, consider the environmental conditions they will be exposed to, such as humidity, temperature fluctuations, and pollution levels. This can significantly impact their performance and longevity.

Another important type of busbar insulator is glass insulators, which provide excellent electrical insulation and can be visually inspected for damage. They are often used in high-voltage applications where transparency to light can help in monitoring the condition of the insulator. Each type of insulator has its unique benefits depending on the specific requirements of the electrical system.

**Tip:** Regular maintenance and inspections can prolong the life of busbar insulators. Look for signs of wear or failure, especially in installations exposed to harsh conditions.

When selecting busbar insulators for electrical systems, several critical factors must be taken into account to ensure optimal performance and safety. One of the primary considerations is the environmental conditions in which the insulators will operate. Variables such as temperature, humidity, and exposure to contaminants like dust or salt can significantly impact the insulating properties. According to a recent industry report by the International Electrotechnical Commission (IEC), choosing insulators that can withstand extreme environmental conditions can enhance operational reliability by up to 25%.

Another essential factor influencing the selection process is the electrical rating of the busbar system. Insulators must be able to handle the voltage levels and fault currents expected in the application. For instance, insulators used in high-voltage installations need to meet stringent dielectric strength requirements, often quantified in kV/mm. The IEEE Standard 48 highlights that improperly rated insulators may lead to failures and increased maintenance costs, emphasizing the importance of thorough electrical analysis.

Tips: Always consult manufacturer specifications and independent testing reports when evaluating potential insulators. Conducting a site-specific assessment can also help in determining the most suitable materials for your application. For longevity and reliability, consider insulators that exceed current operational standards and have a proven track record in similar applications.

This chart represents the different factors influencing the selection of busbar insulators in electrical systems. Each factor is assessed based on its influence level, indicating its importance in the overall functionality of busbar insulators.

Proper maintenance of busbar insulators is crucial for ensuring their longevity and effective performance in electrical systems. Regular visual inspections should be conducted to check for any signs of wear, damage, or contamination. Insulators can accumulate dirt, dust, and moisture, which can lead to electrical tracking or short circuits. Using a soft brush or non-abrasive cloth to clean the insulators can significantly reduce the risk of these issues. Additionally, inspecting for cracks or physical defects will help identify potential problems before they escalate.

Another important aspect of maintenance is the monitoring of environmental conditions. Busbar insulators are often exposed to varying weather conditions, which can affect their lifespan. Installing protective covers can mitigate the impact of UV rays, rain, and extreme temperatures. Furthermore, maintaining appropriate humidity levels in installations near moisture can prevent deterioration. Regular testing of insulator resistance can also provide valuable insights into their condition, ensuring that any faults can be addressed promptly and effectively. By following these maintenance tips, the reliability and functionality of busbar insulators can be significantly enhanced.

Busbar insulators play a crucial role in maintaining the integrity of electrical systems by supporting and insulating busbars, which conduct electricity. However, they can encounter various issues that may affect their performance. Common problems include erosion, cracking, and contamination, which can arise from environmental factors like humidity and temperature fluctuations. These issues can lead to increased electrical resistance, reduced efficiency, or even system failures.

To troubleshoot problems with busbar insulators, a thorough inspection is essential. First, visually examine the insulators for any visible signs of damage, such as cracks or signs of wear. Next, conduct insulation resistance testing to evaluate the effectiveness of the insulators. If the readings are below acceptable levels, it may indicate degradation or contamination, necessitating cleaning or replacement. Additionally, ensure that the busbar connections are secure and free from corrosion, which can exacerbate insulation issues. Regular maintenance and prompt attention to these common problems can help ensure the reliable operation of electrical systems.