Leave Your Message

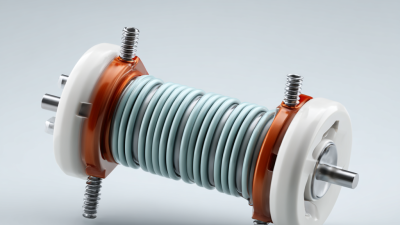

As the 138th Canton Fair approaches in 2025, the spotlight will once again shine on BMC insulators, a pivotal component in the electrical and electronics sector. Recent industry reports indicate a surge in demand for BMC (Bulk Molding Compound) materials due to their excellent thermal stability and electrical insulation properties, projected to grow at a CAGR of 5.3% through 2030. This growth is driven by increasing applications in high-voltage electrical equipment and renewable energy solutions. The Canton Fair serves as an essential platform for industry stakeholders to explore innovative advancements in BMC insulator technology, which not only enhance product reliability but also meet evolving regulatory standards. With a focus on sustainability and efficiency, the fair will provide critical insights into market trends, enabling manufacturers and suppliers to align with global demands and technological advancements in the production of BMC insulators.

As the 138th Canton Fair approaches in 2025, the spotlight will once again shine on BMC insulators, a pivotal component in the electrical and electronics sector. Recent industry reports indicate a surge in demand for BMC (Bulk Molding Compound) materials due to their excellent thermal stability and electrical insulation properties, projected to grow at a CAGR of 5.3% through 2030. This growth is driven by increasing applications in high-voltage electrical equipment and renewable energy solutions. The Canton Fair serves as an essential platform for industry stakeholders to explore innovative advancements in BMC insulator technology, which not only enhance product reliability but also meet evolving regulatory standards. With a focus on sustainability and efficiency, the fair will provide critical insights into market trends, enabling manufacturers and suppliers to align with global demands and technological advancements in the production of BMC insulators.

At the 138th Canton Fair 2025, the spotlight is on the future innovations in BMC insulators, showcasing emerging trends that are set to transform the industry. Advances in materials science are leading to the development of more efficient and sustainable BMC insulators, designed to enhance performance while reducing environmental impact. Exhibitors are presenting cutting-edge designs that promise improved thermal resistance and electrical insulation properties, which are crucial as the demand for reliable and durable insulation solutions grows.

Tips for attendees: When exploring the innovations displayed, consider engaging with manufacturers to understand the practical applications of their new products. Ask about the testing processes that ensure the reliability and safety of these insulators. Networking with industry professionals can also provide invaluable insights into future trends and how they might affect your business or projects.

Additionally, pay attention to the integration of smart technologies in BMC insulation manufacturing. Innovations such as IoT capabilities and smart monitoring systems are being introduced, allowing for real-time performance tracking and maintenance alerts. Embracing these technologies can position your operations at the forefront of the evolving market landscape.

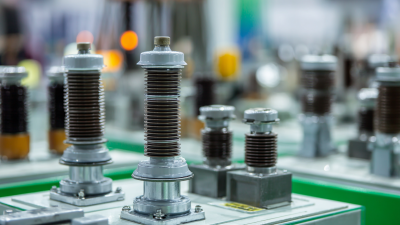

As we approach the 138th Canton Fair in 2025, the BMC (Bulk Molding Compound) insulator industry is poised for substantial evolution, driven by emerging market dynamics and technological advancements. Recent analysis indicates a significant growth forecast for the data center busway market, which is expected to expand at a compound annual growth rate (CAGR) of over 10% through 2025. This growth is reflective of the increasing demand for efficient electrical distribution systems in data centers, ultimately benefiting the BMC insulator manufacturers who play a critical role in ensuring reliability and performance.

The rising trend towards renewable energy and electric vehicles is further influencing the BMC insulator market. Data suggests that the global shift towards sustainable infrastructure is anticipated to boost the adoption of advanced materials. BMC insulators, known for their lightweight and durable properties, are already attracting interest in various applications across the green energy sector. As the market dynamics evolve, stakeholders at the Canton Fair will gain valuable insights into innovative solutions that align with these industry trends, paving the way for future growth and collaboration within the BMC insulator landscape.

At the 138th Canton Fair in 2025, the focus on sustainability in the manufacturing of BMC (Bulk Molding Compound) insulators is set to reshape industry practices. With increasing emphasis on eco-friendly methodologies, manufacturers are exploring innovative technologies that reduce environmental impact while enhancing product performance. The integration of recyclable materials into BMC formulations is one such trend, promoting not only energy efficiency but also the responsible disposal of products at the end of their lifecycle.

**Tips:** When considering suppliers for BMC insulators, prioritize those who demonstrate a commitment to sustainable practices. Inquire about their use of renewable resources and their strategies for minimizing waste during production. This not only supports environmentally friendly initiatives but can also enhance your reputation as a responsible business.

In addition to materials, advancements in production techniques are gaining traction. Techniques such as energy-efficient molding processes and closed-loop water systems are becoming standard in leading manufacturing units. These practices not only lower carbon footprints but also significantly reduce operational costs in the long run.

**Tips:** Stay informed about the latest innovations in BMC technology. Regularly engaging with industry publications and attending conferences can provide insights into best practices and emerging trends that align with sustainable development goals.

| Dimension | Description | Technology/Practice | Sustainability Impact |

|---|---|---|---|

| Material Innovation | Utilization of bio-based and recycled materials in BMC insulators. | Introduction of biodegradable polymers. | Reduced environmental footprint. |

| Energy Efficiency | Enhancing insulation properties to reduce energy consumption in applications. | Advanced thermal management technologies. | Lower greenhouse gas emissions. |

| Circular Economy | Development of products designed for disassembly and recycling. | Implementing take-back schemes. | Minimized waste generation. |

| Lifecycle Assessment | Conducting assessments to evaluate environmental impacts across product lifecycle. | Utilization of LCA software tools. | Informed decision-making for sustainability improvements. |

| Regulatory Compliance | Adhering to international sustainability standards and regulations. | ISO 14001 certification. | Enhanced marketability and consumer trust. |

At the 138th Canton Fair in 2025, BMC (Bulk Molding Compound) insulators stand to benefit from enhanced networking and collaboration opportunities among manufacturers and industry stakeholders. As global demand for energy-efficient materials continues to rise, BMC insulators are gaining traction due to their superior thermal and electrical properties. According to a recent report by ResearchAndMarkets, the global BMC market is projected to grow at a CAGR of 5.7% between 2023 and 2030, driven primarily by increasing applications in the electrical and electronics sector.

The Canton Fair serves as an ideal platform for BMC insulator manufacturers to forge partnerships and explore innovative solutions. Industry leaders are increasingly recognizing the importance of collaboration to enhance product development and sustainability efforts. A survey conducted by MarketWatch revealed that approximately 68% of manufacturers emphasize the necessity of strategic alliances to adapt to evolving market demands. By building connections at the Canton Fair, manufacturers can share insights, address regulatory challenges, and collectively drive advancements that meet the needs of modern infrastructure projects. This interplay of networking and collaboration is essential in reinforcing the competitive edge of BMC insulators in a rapidly changing marketplace.

At the 138th Canton Fair in 2025, BMC (Bulk Molding Compound) insulators are set to play a pivotal role in shaping future infrastructure development. These innovative materials are poised to address the sustainability and performance demands of modern electrical systems. With their excellent thermal stability, electrical insulating properties, and mechanical strength, BMC insulators are becoming increasingly vital in sectors such as renewable energy, transportation, and smart grid technology. As urban areas continue to expand and the need for reliable energy distribution grows, BMC insulators are positioned to enhance the efficiency and longevity of critical infrastructure.

The global market for BMC insulators is witnessing significant growth driven by advancements in material science and rising investments in renewable energy projects. Industry leaders gather at the Canton Fair to exchange insights on trends such as lightweight construction and eco-friendly materials. The shift towards greener technologies emphasizes the necessity for materials that not only offer superior performance but also minimize environmental impact. As major players in the electrical and construction industries recognize the potential of BMC insulators, collaborations and innovations are likely to shape the future landscape of infrastructure development significantly.