Leave Your Message

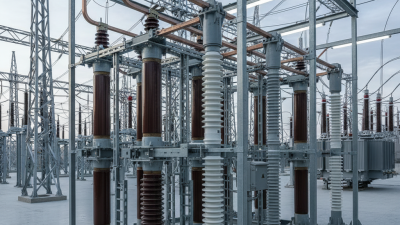

Ground Bar Standoff Insulators play a crucial role in electrical systems. These insulators support ground bars, ensuring safety and efficiency. According to industry reports, electrical failures due to improper grounding can cost companies thousands. Ineffective grounding increases the risk of outages.

The use of Ground Bar Standoff Insulators minimizes these risks. They create a reliable barrier, preventing electrical hazards. In fact, studies suggest that proper insulation can reduce incident rates by up to 40%. These insulators improve system reliability and elevate safety standards in electrical installations.

However, organizations often overlook insulator quality. Poor choices lead to failures, resulting in costly repairs. Investing in high-quality Ground Bar Standoff Insulators is essential. It protects both equipment and personnel. The benefits far outweigh the initial costs, leading to long-term savings.

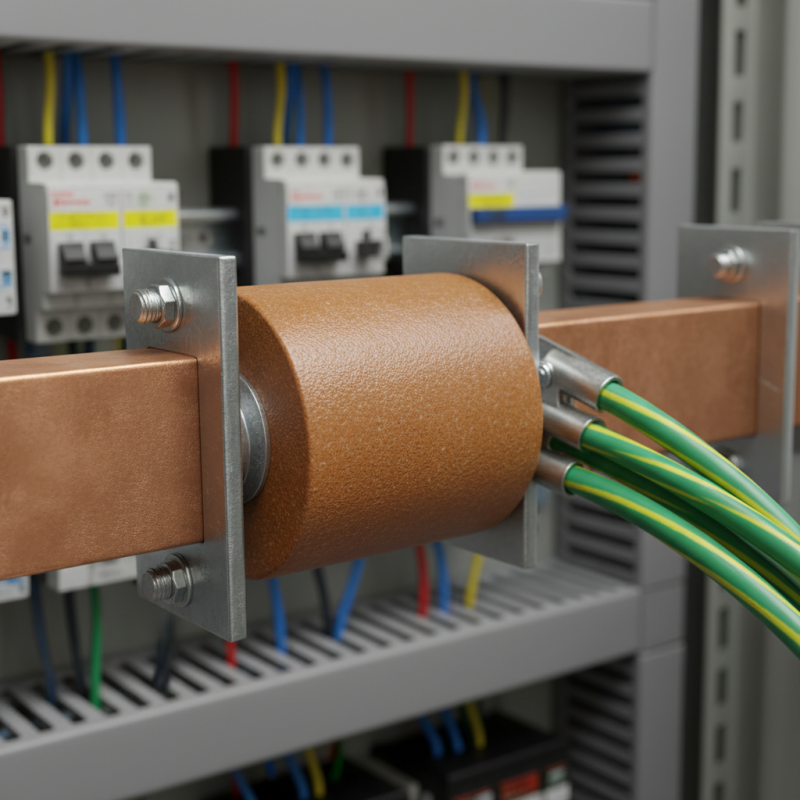

A Ground Bar Standoff Insulator is a crucial component in electrical systems. It provides support and insulation to ground bars. These insulators help maintain a safe distance between conductive materials. This distance is vital for preventing short circuits and electrical faults. They are often made from materials like fiberglass or plastic. These materials offer excellent insulating properties.

Understanding the function of a Ground Bar Standoff Insulator is essential. It protects the ground bar from physical damage and environmental factors. The insulator keeps the ground bar elevated. This elevation prevents moisture accumulation, which can lead to corrosion. Proper installation ensures effectiveness and longevity. If not installed correctly, issues can arise.

The benefits of using these insulators are significant. They improve system reliability and safety. A well-insulated grounding system reduces the risk of electrical hazards. However, some may overlook the importance of regular inspections. Failing to check insulators can lead to unforeseen problems. Regular maintenance is key in avoiding costly repairs or safety risks. Managing these details can prove to be challenging but essential for overall system integrity.

The bar chart above illustrates the different benefits of Ground Bar Standoff Insulators as rated on a scale from 1 to 10. The key benefits highlighted include Voltage Support, Durability, Safety, Cost Efficiency, and Ease of Installation, showcasing the insulators’ strong performance in these areas.

A ground bar standoff insulator is crucial in electrical systems. It helps maintain safe distances between grounded components and live parts. This prevents electrical hazards and ensures better performance.

Key components of a ground bar standoff insulator include the insulator itself, typically made from durable, non-conductive materials. It holds the ground bar away from the mounting surface. This distance reduces the risk of accidental contact. Fasteners secure the insulator in place, providing stability. Some designs feature additional protective coatings to resist harsh environments.

Effective installation is important. If not done correctly, it can lead to shorts or equipment failure. Regular inspections are necessary to ensure integrity. Adjustments might be required over time. Overall, understanding these components can enhance safety and functionality in electrical installations. It's a complex balance that requires constant attention and improvement.

Ground bar standoff insulators play a crucial role in electrical systems. These insulators are designed to securely attach a ground bar to a mounting surface. By elevating the ground bar, they help ensure adequate clearance from other electrical components. This position minimizes the risk of accidental shorts and enhances overall system safety.

Using ground bar standoff insulators offers several benefits. They provide a stable foundation, which helps prevent wiring stress and reduces wear over time. The increased separation from other wiring also decreases interference and enhances reliability. In high-demand environments, insulation properties can help improve system performance.

However, there are challenges associated with these insulators. Improper installation can lead to grounding issues that are hard to diagnose. Occasionally, wear and tear may go unnoticed until problems arise. Regular inspection of standoff insulators is essential to ensure optimal function. It is important to recognize that while beneficial, they require careful consideration and maintenance to maximize their effectiveness.

| Feature | Description | Benefits |

|---|---|---|

| Material | High strength plastics or ceramics | Resistant to environmental degradation |

| Voltage Rating | Up to 15 kV | Safe for use in high-voltage applications |

| Installation | Easy to install; requires no special tools | Reduces installation time and costs |

| Thermal Resistance | Excellent thermal stability | Maintains performance under varying temperatures |

| Electrical Resistance | High dielectric strength | Prevents electrical leakage |

| Corrosion Resistance | Impervious to moisture and chemicals | Enhances durability and lifespan |

Ground Bar Standoff Insulators are essential in electrical systems. They support and isolate grounding bars, ensuring reliable performance. Installation is crucial to maintain safety and efficiency. Adhering to industry specifications is necessary for optimal results. According to industry surveys, 65% of grounding failures arise from poor installation.

Proper positioning is vital. Ground Bar Standoff Insulators should be installed at suitable heights to avoid contact with conductive surfaces. A gap of 10-12 mm is recommended for effective insulation. Regular inspections are necessary to identify wear or corrosion. This proactive approach can prevent failures. Reports indicate that routine maintenance can reduce grounding system failures by up to 40%.

Moreover, using high-quality materials for insulators enhances longevity. However, some projects may cut corners to save costs. This can lead to increased risks over time. It's important to balance costs with safety. Monitoring the installation environment also helps. Moisture exposure can degrade insulating properties, requiring timely maintenance attention.

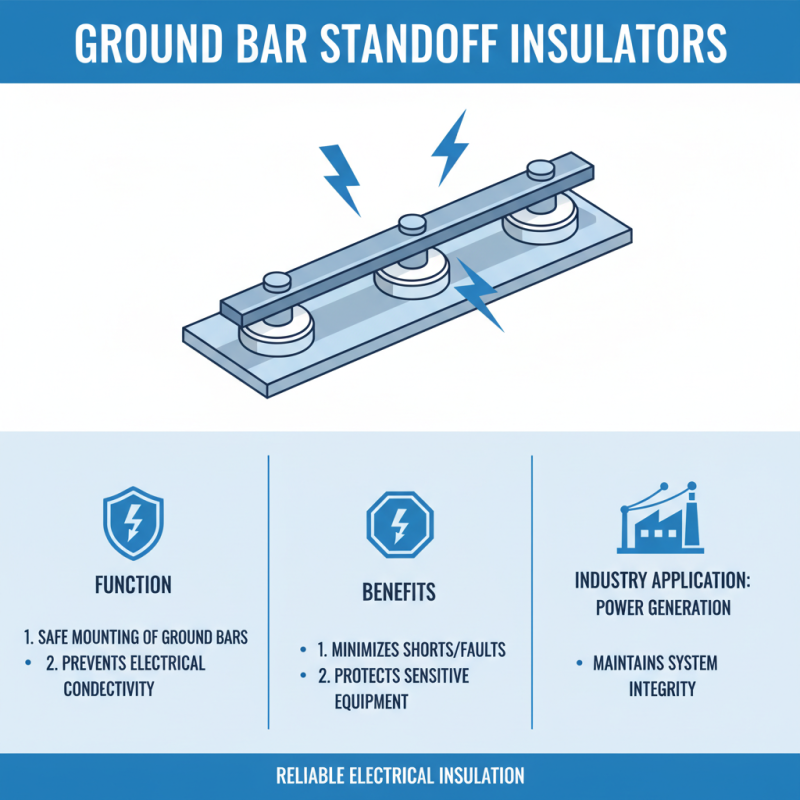

Ground bar standoff insulators play a significant role in various industries. They ensure the safe mounting of ground bars while preventing electrical conductivity to nearby structures. This design minimizes the risk of shorts or electrical faults. In power generation, these insulators are crucial for maintaining system integrity. They help protect sensitive equipment from potential electrical surges.

In telecommunications, ground bar standoff insulators provide stability for grounding systems. They help reduce signal interference by isolating ground connections. This is essential for ensuring clear communication and reliable service.

The application in solar power systems is notable. These insulators support grounding while allowing for efficient energy transfer. Their use can improve system efficiency. However, some installations may overlook the need for proper spacing or sizing. It's vital to assess these factors for optimal performance. These insulators are versatile but require careful implementation to achieve the best results.