Leave Your Message

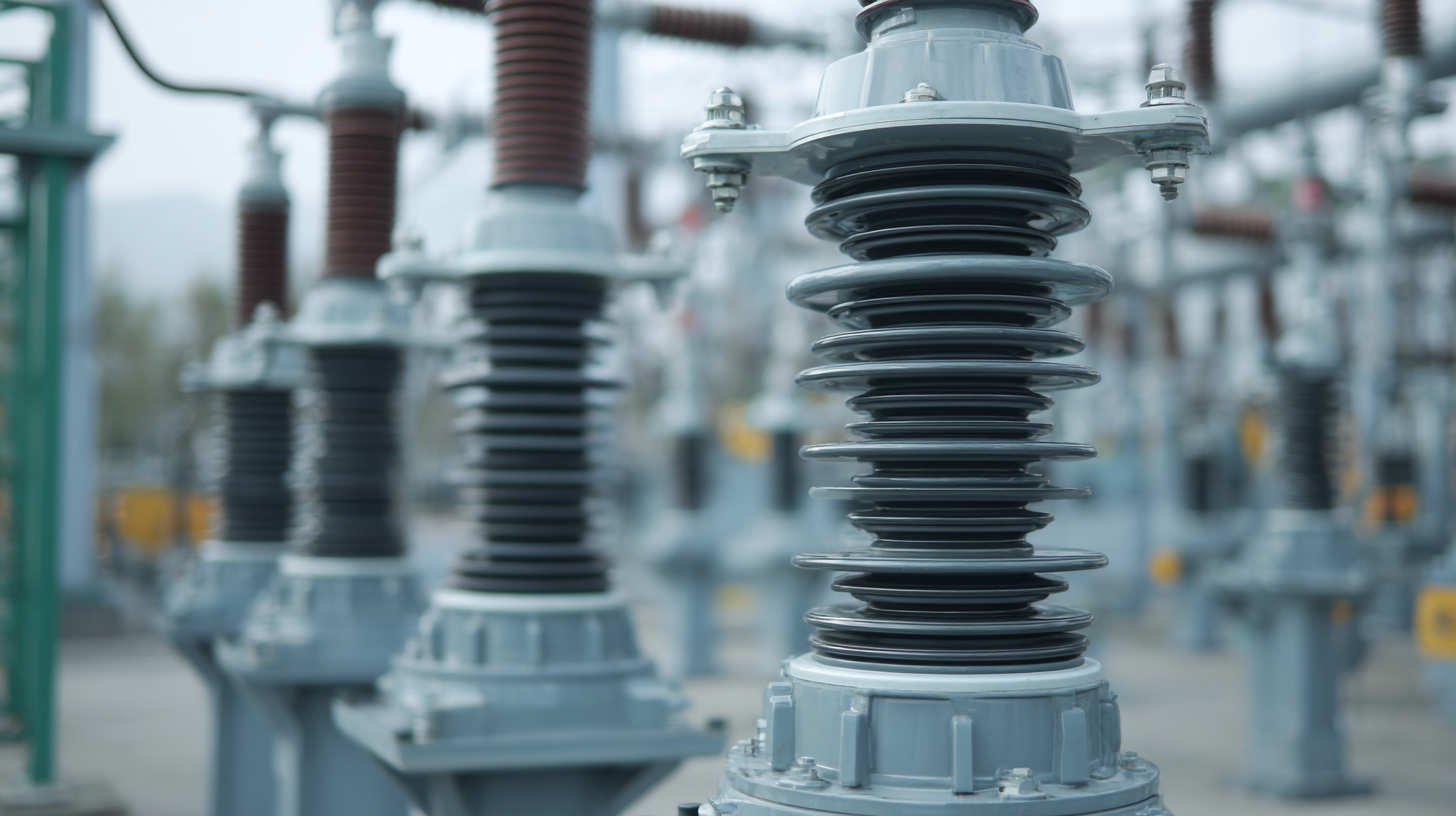

As the global demand for robust electrical infrastructure grows, the role of Composite Insulators has become increasingly critical in ensuring safety and reliability in power transmission systems. According to a recent market analysis report by Global Industry Analysts, the composite insulator market is projected to reach USD 2.7 billion by 2025, reflecting a significant compound annual growth rate (CAGR) of 5.2% during the forecast period. This surge is driven by the rising need for enhanced performance in electrification projects and the shift towards renewable energy sources, which demand superior insulating materials.

Premier Composite Insulators, strategically positioned in China, exemplifies the quality manufacturing needed to meet these escalating global demands. By focusing on innovation and adherence to international standards, the company not only contributes to the local economy but also plays a vital role in supplying the world with high-performance insulators essential for sustainable energy solutions.

In the highly competitive field of electrical insulators, Premier Composite Insulators stands out by prioritizing quality assurance throughout its manufacturing processes. According to a recent report by Research and Markets, the global composite insulator market is projected to reach $1.2 billion by 2025, driven by the increasing demand for reliable and efficient electrical infrastructure worldwide. This growth emphasizes the critical need for manufacturers like Premier Composite Insulators, who are committed to excellence and quality control at every step of production.

Premier Composite Insulators employs rigorous testing protocols and adheres to international standards such as ASTM and IEC to ensure the durability and performance of their products. Their commitment is reflected in a quality assurance program that involves comprehensive inspections and continuous monitoring. The company has reported that over 95% of their current customers rate their satisfaction levels as excellent, reinforcing the trust and reliability they have built in the industry. As demand for high-performance insulators rises, Premier Composite Insulators remains dedicated to upholding superior quality, aligning with global standards to meet the evolving needs of their clients.

| Dimension | Indicator | Result | Remarks |

|---|---|---|---|

| Material Quality | Certification Standards | ISO 9001, ISO 14001 | Meets international quality standards |

| Production Processes | Error Rate | < 1% | Minimized errors through training |

| Supplier Relationships | Supplier Evaluation Score | 95/100 | Strong partnerships ensure quality |

| Waste Management | Recycling Rate | 75% | Commitment to sustainability |

| Employee Training | Training Hours per Employee | 40 hours/year | Focus on skill enhancement |

Premier Composite Insulators has positioned itself as a leader in the electrical insulation industry through its commitment to innovative technology and quality manufacturing. By leveraging advanced materials and cutting-edge production techniques, the company offers products that meet the rigorous demands of various global markets. Their proprietary composite materials not only enhance performance but also provide enhanced durability, making them suitable for diverse applications, from power generation to transmission.

What truly sets Premier Composite Insulators apart is their relentless pursuit of technological advancement. The company invests significantly in research and development, enabling them to stay ahead of industry trends and continuously improve their product offerings. This forward-thinking approach allows them to create customized solutions tailored to the unique challenges faced by their clients. By prioritizing innovation, Premier Composite Insulators not only meets current market needs but also anticipates future demands, ensuring that their products remain at the forefront of the electrical insulation sector.

In the ever-evolving landscape of electrical utilities, Premier Composite Insulators stands as a beacon of quality manufacturing from China, tailored to meet global demands. As the renewable energy sector rapidly expands, the need for advanced insulation solutions has surged. According to a recent report by MarketsandMarkets, the global composite insulator market is projected to reach USD 5.2 billion by 2025, driven by the increasing investments in modern power infrastructure. This solid growth underscores the significance of high-performance insulation products in enhancing system reliability and efficiency.

Premier Composite Insulators has strategically forged partnerships across continents, ensuring their solutions are adept at addressing the diverse needs of various markets. By leveraging cutting-edge materials and innovative manufacturing techniques, they provide insulators that not only withstand extreme environmental conditions but also comply with stringent international standards. The International Energy Agency reported that renewable energy sources are expected to account for 80% of global electricity generation by 2050. This transition emphasizes the critical role of durable composite insulators in supporting the infrastructure of future energy systems worldwide.

In today's rapidly evolving manufacturing landscape,

environmental sustainability

is not just a trend, but a necessity.

Premier Composite Insulators stands at the forefront of this movement,

implementing innovative practices that minimize ecological impact

while ensuring the highest quality in composite insulator production.

By utilizing eco-friendly materials

and advanced technologies, the company exemplifies how the manufacturing sector

can balance industrial efficiency with environmental responsibility.

The commitment to sustainable practices goes beyond just materials; Premier Composite Insulators

is dedicated to reducing waste and energy consumption

throughout the production process. Their facilities employ

renewable energy sources

and recycling initiatives that significantly lower the carbon footprint

associated with manufacturing.

This holistic approach not only safeguards the environment

but also sets a benchmark for industry peers, demonstrating that

profitability and sustainability can coexist harmoniously.

The insulation industry is witnessing a significant transformation, driven by technological advancements and increasing demand for sustainable solutions. Premier Composite Insulators is at the forefront of this evolution, focusing on producing high-quality insulation materials that meet global standards. According to a recent report by MarketsandMarkets, the global insulation market is expected to reach $62.5 billion by 2026, growing at a CAGR of 5.4%. This surge underscores the necessity for advanced products that offer superior performance while being environmentally friendly.

In response to these trends, Premier Composite Insulators is prioritizing innovation and sustainability in their manufacturing processes. The company is integrating advanced composite materials that not only enhance thermal efficiency but also comply with stringent environmental regulations. Industry experts indicate that composites can reduce energy consumption by up to 30%, reinforcing their role as a cornerstone in modern insulation solutions.

**Tip:** When selecting insulation materials, consider not just thermal resistance but also their lifecycle impact. Sustainable options like eco-friendly composites can provide long-term savings and a smaller carbon footprint. Additionally, always analyze the certifications of insulation products to ensure compliance with international standards, which can be crucial for both safety and performance.