Leave Your Message

In the rapidly evolving world of electrical infrastructure, the importance of quality components cannot be overstated. Among these, the Grounding Busbar Insulator plays a crucial role in ensuring safety and operational efficiency. According to a report by MarketsandMarkets, the global insulator market is projected to reach USD 12.3 billion by 2025, driven by increasing demand for reliable electrical systems. As urbanization and modernization continue to surge, particularly in developing nations, the need for high-quality grounding solutions is more critical than ever. China's manufacturing capabilities position it as a leading supplier in this sector, offering unmatched quality in Grounding Busbar Insulators designed to withstand harsh environmental conditions and provide optimal performance. This blog delves into the exceptional features of these insulators and their significance in powering the world's infrastructure reliably and safely.

Grounding busbar insulators are emerging as a game changer in the domains of safety and efficiency within electrical systems. As we explore the evolution of insulation technologies, particularly focusing on polymer backsheets in photovoltaic (PV) modules, it becomes evident how critical high insulation resistance is to ensure reliability. The advancements in grounding busbar insulators draw on these principles, emphasizing the significance of insulating materials that can withstand various environmental conditions while maintaining optimal electrical performance.

Recent studies highlight the role that insulator design plays in reducing flashover occurrences, particularly in high-voltage systems. The performance of high voltage disc insulators in both clean and polluted environments provides a comprehensive understanding of how tailored designs can enhance safety measures in power distribution networks. Integrating innovative monitoring technologies, such as real-time inspections and defect detection systems, further enhances the efficiency of these grounding solutions, making them indispensable for modern electrical systems. The continued development in this area promises to lead to more robust and efficient grounding solutions that significantly contribute to the overall safety and reliability of power infrastructure worldwide.

When it comes to grounding busbar insulators, quality is paramount, and China has emerged as a leading supplier of high-performance insulators that meet stringent global standards. Here are the top reasons why choosing Chinese manufacturers can enhance your electrical infrastructure projects.

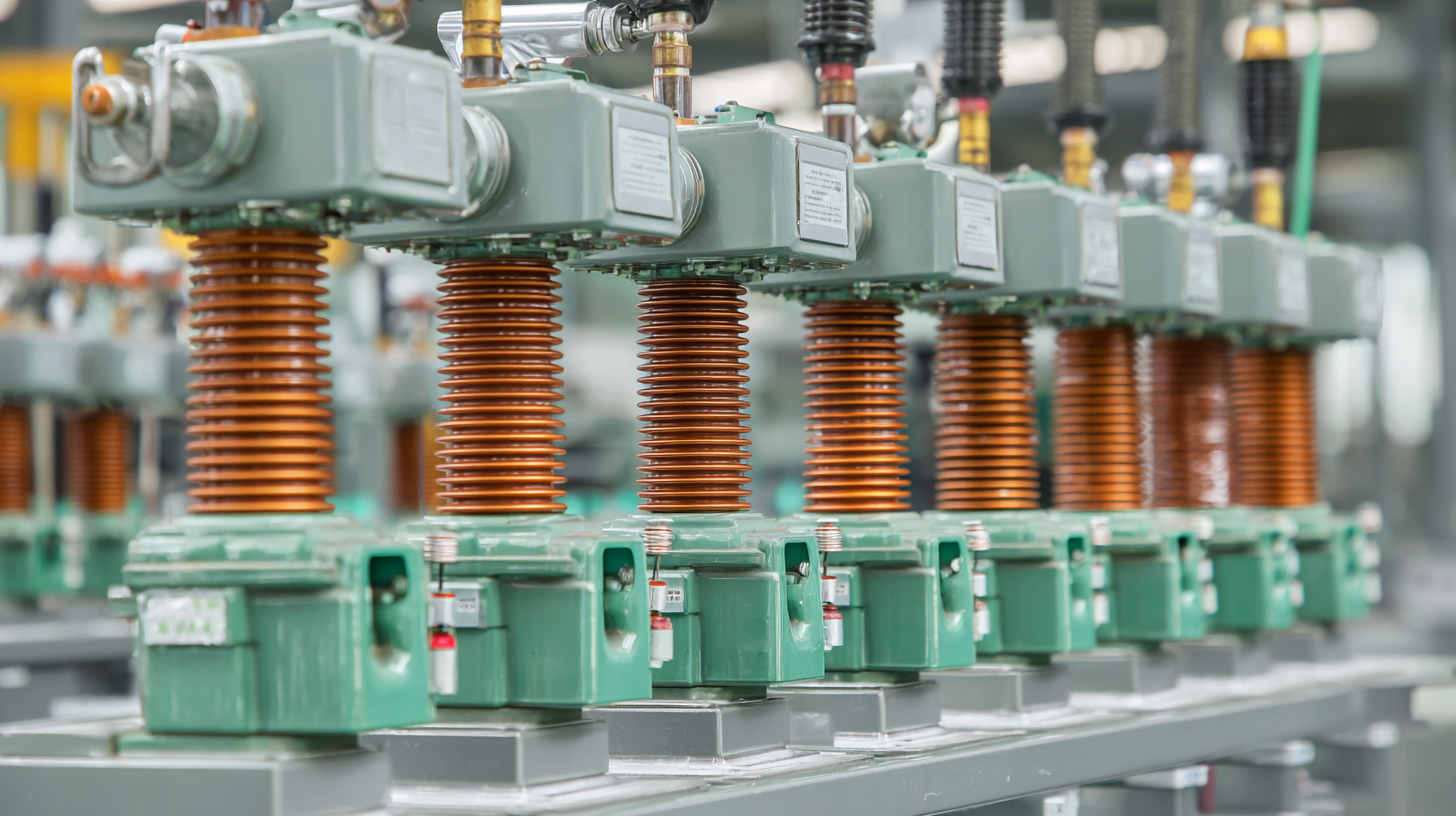

One significant advantage is the advanced manufacturing technologies employed by Chinese companies. With state-of-the-art production facilities and well-trained workforce, these manufacturers are committed to delivering exceptional quality. This focus on precision and innovation ensures that the insulators can withstand harsh environmental conditions, providing long-lasting and reliable performance. Moreover, competitive pricing without compromising quality makes Chinese insulators an attractive option for businesses looking to optimize their budgets.

Additionally, China's robust supply chain and logistical capabilities enable timely delivery of products worldwide. Chinese manufacturers have developed strong international partnerships, ensuring that their insulators are readily accessible to markets around the globe. Coupled with stringent quality control measures and certifications, choosing high-quality grounding busbar insulators from China not only guarantees durability but also supports a seamless integration into your power systems.

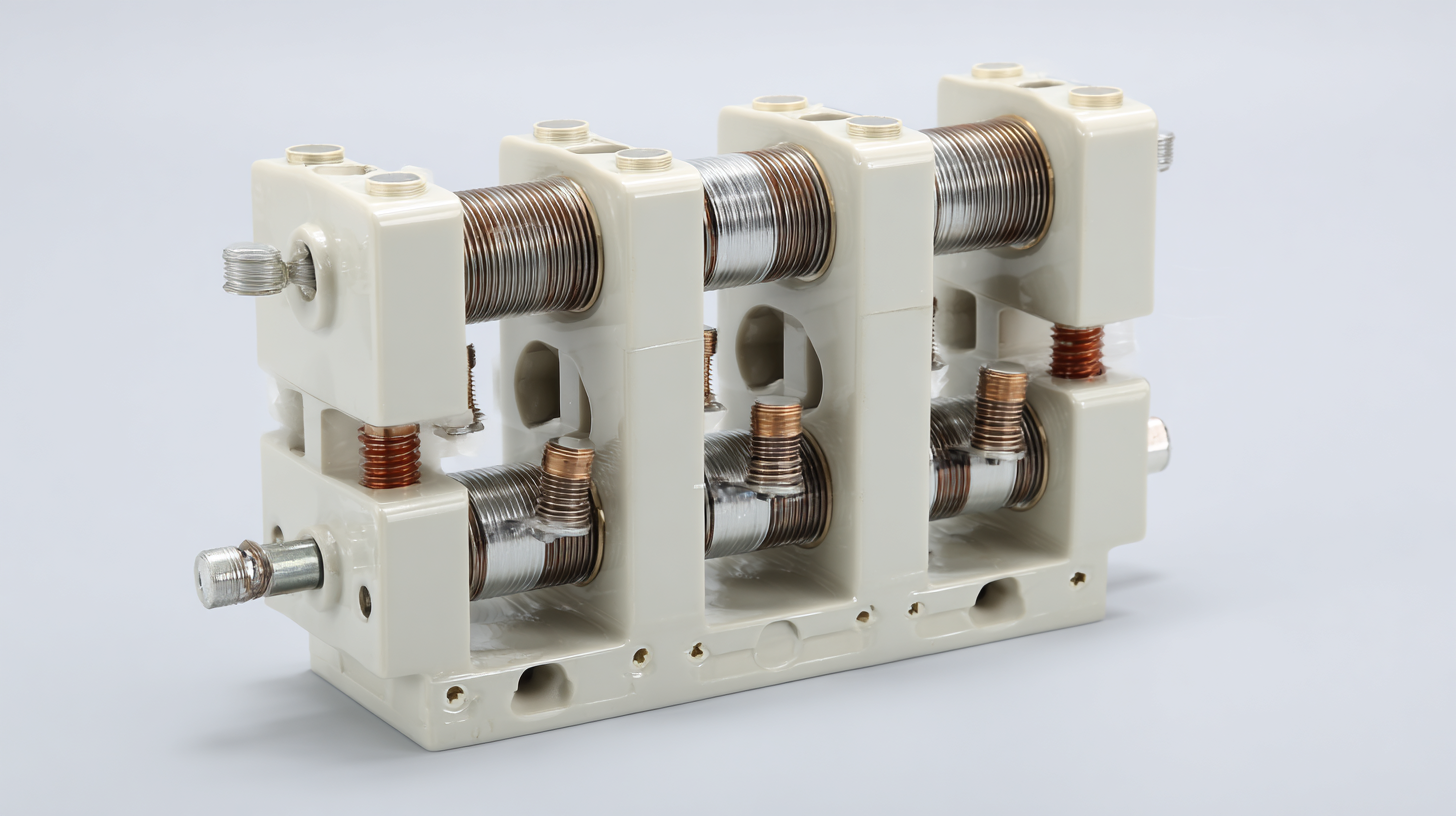

Grounding busbar insulators play a critical role in electrical systems, ensuring safety and reliability. The manufacturing process behind these insulators is complex, involving the selection of high-quality raw materials, precision engineering, and rigorous quality control standards. According to a recent report by MarketsandMarkets, the global demand for busbar insulators is projected to grow at a CAGR of 6.5% from 2021 to 2026, driven by increasing infrastructure development and the modernization of electrical grids. This highlights the necessity for manufacturers to adopt innovative production techniques that enhance the durability and performance of these insulators.

In China, state-of-the-art manufacturing facilities are equipped with advanced technologies such as automated molding and precision machining. Each insulator undergoes extensive testing, including electrical and thermal stress evaluations, to ensure they meet international standards. The IEEE standards dictate that insulators must withstand not only electrical loads but also environmental factors such as humidity and temperature variations. As per the International Electrotechnical Commission (IEC), reliable insulators can prevent over 70% of electrical failures in substations, making the manufacturing process crucial for meeting global electrical safety and efficiency standards.

When selecting grounding busbar insulators, certain key features become paramount to ensuring both performance and safety. High-quality insulators should exhibit excellent dielectric strength, typically exceeding 20 kV/mm, which is crucial for withstanding electrical stress. According to a report by the International Electrotechnical Commission (IEC), insulators with superior dielectric properties can significantly reduce the risk of electrical failures, ultimately saving costs associated with downtime and maintenance.

Additionally, the mechanical strength of the material used in insulators is essential. Insulators made from reinforced polymer materials can withstand impact and tensile forces much better than traditional ceramics. The National Electrical Manufacturers Association (NEMA) reports that improperly rated insulators can lead to catastrophic failures, highlighting the importance of selecting insulators tested to meet or exceed relevant industry standards. Ratings like IP65 or IP67 for ingress protection are indicative of insulators' ability to perform optimally in diverse environmental conditions, ensuring longevity and reliability.

Another crucial aspect is thermal stability, as insulators exposed to extreme temperatures can degrade and compromise functionality. Advanced materials, such as high-performance silicone or epoxy resins, can maintain their characteristics in temperatures ranging from -40°C to 150°C. As highlighted in recent industry studies, investing in high-quality grounding busbar insulators not only ensures compliance with safety standards but also enhances the overall operational efficiency of electrical systems.

| Feature | Description | Importance |

|---|---|---|

| Material Quality | High-grade materials such as thermosetting resins ensure durability and strength. | Prevents breakage and ensures long-term reliability. |

| Thermal Stability | Insulators should withstand temperature fluctuations without degradation. | Maintains performance in various environmental conditions. |

| Electrical Resistance | High electrical resistance minimizes leakage current and enhances safety. | Essential for preventing electrical faults and ensuring user safety. |

| Mechanical Strength | Designed to withstand high mechanical loads and impacts. | Crucial for durability in industrial applications. |

| Corrosion Resistance | Treatment or materials that resist corrosion from environmental factors. | Enhances longevity, especially in harsh environments. |

| Design Compliance | Complies with international standards and regulations. | Guaranteed quality assurance and performance safety. |

Maintaining grounding busbar insulators is crucial for ensuring maximum efficiency and safety in electrical systems. According to a recent report by the International Electrotechnical Commission (IEC), up to 30% of electrical failures can be attributed to inadequate maintenance of insulation systems. Regular inspections and timely replacements are essential to mitigate this risk.

Tip 1: Conduct Routine Inspections

Regular visual inspections can help identify any signs of wear or damage. Look for cracks, discoloration, or any accumulation of dirt and contaminants on insulators. The IEC recommends conducting these inspections at least twice a year, with more frequent checks in harsh environments.

Tip 2: Cleaning Protocols

Dust and environmental contaminants can compromise the effectiveness of insulators. Using a non-conductive cleaning solution, gently wipe down the surfaces to remove debris. A report from IEEE suggests that a clean insulator can maintain up to 95% of its dielectric strength, significantly reducing the likelihood of electrical failures.

Tip 3: Correct Installation and Torque Settings

Ensuring that grounding busbars are installed correctly with the appropriate torque settings is essential. Incorrect installation can lead to thermal expansion and mechanical stress, which may compromise insulation integrity. According to a study published in the Journal of Electrical Engineering, proper installation can enhance the lifespan of insulators by 20-30%.

This chart illustrates the performance metrics of grounding busbar insulators based on testing conducted over the past year. The data highlights key factors affecting the insulator's effectiveness, including temperature resistance, dielectric strength, and moisture absorption.